A battery for 1 million kilometers? - the secret lies primarily in thermal management

Toyota guarantees the battery of its Lexus UX300e and its Proace electric van for 1 million kilometers over a period of 15 years.

This is a clever move on the part of the Japanese, because up to now the risk with electric vehicles has tended to lie with the buyers.

Volkswagen is being a bit more cautious: VW guarantees one percent for eight years or 160,000 kilometers. In a way, that reminds me of the Duracell bunny ...

Whether the Toyota mileage of 1 million kilometers is actually utilized or whether the vehicles are operated for 15 years is not so important. It is the message that counts: We take the risk off your hands!

Assuming a range of 400 km for the UX300e, this means about 2,500 charging cycles. High-quality battery cells are now expected to last more than 2,000 cycles, so the 2,500 cycles is within the realm of possibility.

The risk for Toyota is therefore manageable, the advertising effect all the greater. Quite apart from that, who drives such distances with an e-vehicle? Finally, there's the fear of getting stuck somewhere in the countryside for lack of time and infrastructure.

Both when charging the battery at the DC fast charger with up to 100 kW charging power and when discharging while driving, a 75 kWh battery should be charged to 80% of its capacity within 45 minutes. So there is time left for driving.

But back to the topic ...

How do you constructively manage such a high number of charging cycles?

The secret lies in the thermal management of the battery!

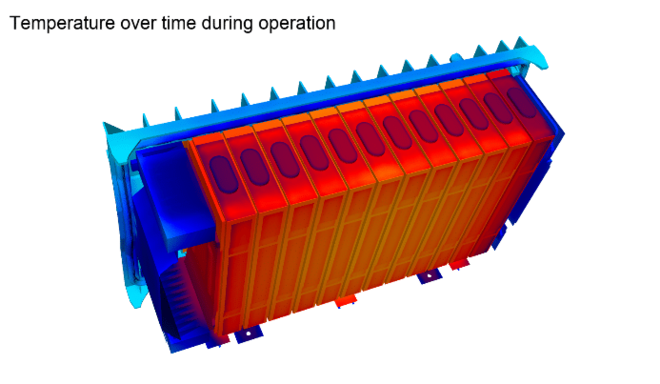

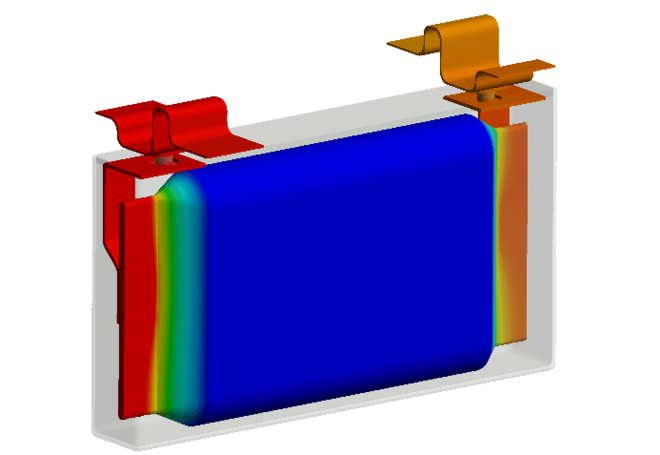

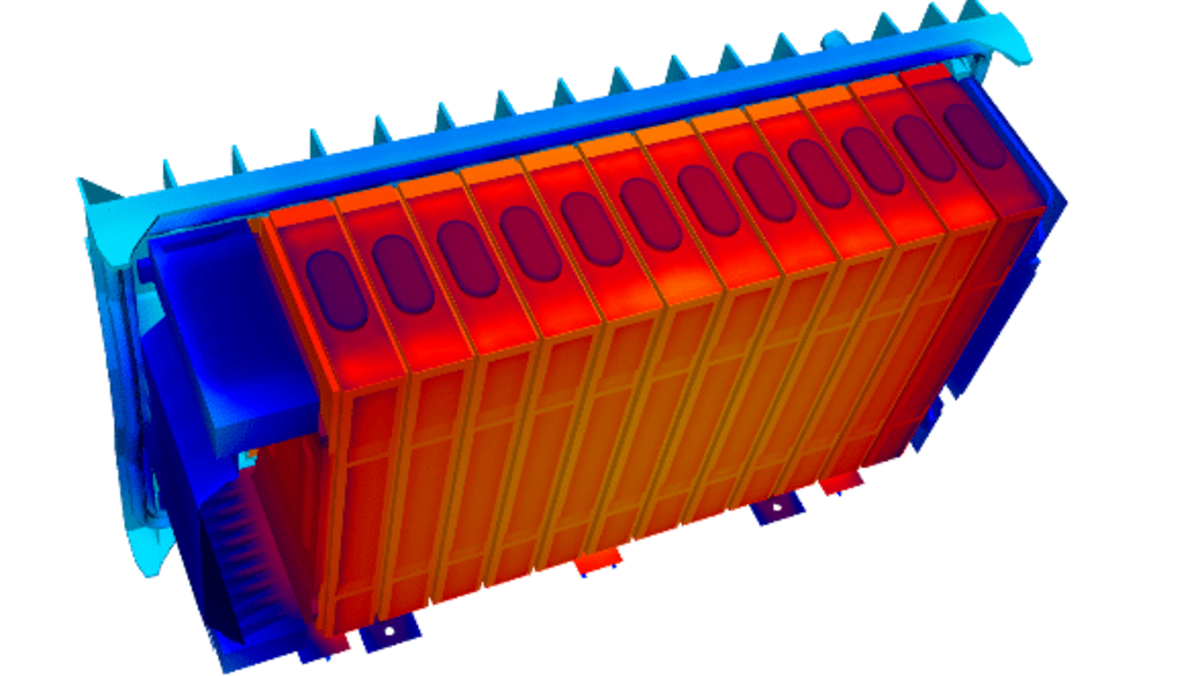

A cooling concept tailored to the requirements is the prerequisite for the longest possible service life. This can ensure uniform temperature distribution and avoid local overheating.

Here, simulations with FEM and CFD are indispensable tools that can be used efficiently during development.

Water-cooled systems have largely prevailed over air cooling. The higher heat flux density of water allows more efficient and accurate temperature control than air.

Electricity and water bite, however, so increased attention must be given to tightness in a water cooling system. Over such a long period of time, seals age and the original sealing force declines to a fraction of its original value.

These are exciting topics, since the empirical values of circuit boards, plastic parts and seals, for example, are no longer worth anything in the case of the combustion engine with its 8,500 h of operating time. After all, the electric vehicle is permanently on standby, being driven or charged. That quickly adds up to over 100,000 hours in 15 years.

Our know-how

Merkle & Partner has been involved with related simulation topics for well over a decade.

Topics are here:

- Temperature development of the battery during charging

- Temperature development of the battery during various driving cycles and ambient conditions

- Heat generation due to current flow

- Electrochemistry in the cells

- Cooling of the cells

- Tightness of the housing

- Pressure tests

- Crash behavior

- Thermomechanical behavior

- Thermal shock

- Short-term and long-term behavior of mechatronic components

- Supervision of necessary tests for material characterization

We use both FEM and CFD tools here, depending on the issue on which the simulation is based.

Are you involved in the development of new electric vehicles or electric motors, fuel cells, battery housings, battery cells, control systems or other components and do you have to ensure that the requirements are met? Benefit here from our many years of unique know-how.

Arrange a non-binding appointment, gladly also via video. We will be happy to inform you how you too can keep pace with the disruptive changes in automotive engineering with us as your simulation partner.

Your Stefan Merkle

PS: Don't miss my blog on the current assessment of the situation in the automotive industry next week.