CFD - Simulation

Numerical flow simulation

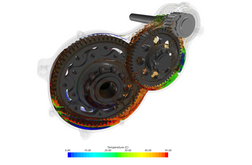

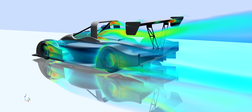

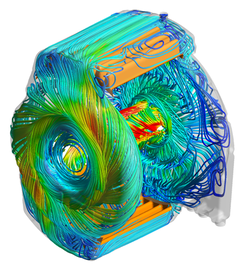

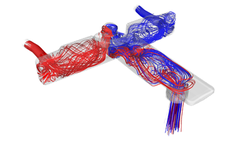

The effects of media such as gases, liquids or bulk materials on components or systems remain hidden to our eye in most cases. The same applies to heat that is added or dissipated in components. CFD simulations make pressures, flow forces and heat flows visible. Thus, calculations in the field of fluid mechanics offer you valuable insights in product and process development.

CFD simulations allow you to know in advance which design makes sense, where you need to adapt components or how to design your product to achieve the highest possible efficiency. The applications of CFD simulation are manifold. The information you can gain from it is enormous.

CFD calculation

Your advantages

Comprehensive insight

CFD calculations can be used to better understand and combine the relationships between pressure, temperature, resulting losses and efficiencies in flowing media, also in connection with chemical reactions. Mixing processes, multiphase flows, free surfaces and particles can also be investigated. Even the acoustic behavior can be analyzed and occurring noise can be reduced.

Efficient development

CFD analysis allows you to detect turbulence, critical temperature gradients and resulting thermomechanical stress peaks early in the design phase. Vary different designs quickly and without costly prototypes and thus optimize your product within a very short time. An enormous time gain!

Quick error analysis

If efficiencies are too poor or temperatures are too high or too low, equipment is too noisy, or mixing processes are inadequate, CFD analysis can offer you insightful insights into finding and fixing the root cause.

Competitive advantages through efficiency and safety

CFD analysis can be used to prove the effectiveness of your system, fan or pump. In addition, the optimal design is found quickly. You save costs and maximize the safety of your product!

When does CFD make sense?

For product development, failure analysis and numerous other applications - from engine cooling to bulk solids processes to cleanrooms, computation of fluid dynamics provides valuable support:

Product development

During the concept phase within product development, approaches are developed from a variety of solution-oriented proposals that best fit the task at hand. In the process, different sections of the product are planned in different working groups and brought together at the end of the concept phase. Often, evaluations of the individual steps are put through their paces qualitatively and quantitatively by means of utility value analyses.

Example CFD: In the concept phase it is discussed which simulations make sense for the product to be simulated. In the process, various scenarios are developed that have an impact on the simulation object.

After the concepts of the various working groups from the concept phase have been brought together, the individual steps themselves are now examined in product development, in addition to the interfaces between the various sections. In this process, small problems and errors that were not discovered in the concept phase are corrected. After this phase, the product should be prepared to the extent that it can be released for modelling.

Example CFD: After all scenarios have been compiled, the framework conditions for the simulation must be defined. In doing so, peculiarities of the object must be taken into account, as well as external circumstances that can influence the simulation.

The functional phase is also known as the prototype phase. Here, the first, finished concept is put into practice and serves to get a first impression of the finished sketched product. The aim is to identify defects that are not apparent on paper and thus make improvements before series production.

Example CFD:

In the functional phase for a CFD simulation, initial tests are carried out without the exact external circumstances in order to test the product without influences. In this way, it can be seen which difference was later caused by the external influence.

The elaboration phase is the phase that implements the previous phases and then comes to the final product development. Here, all the steps that were already discussed in the conception phase in individual groups are elaborated and fed with valid data.

Example CFD: Here, the object is simulated with all external circumstances and with consideration for the peculiarities of the simulation object via CFD simulation. In the process, visual impressions in the form of images and videos are used to provide the results for the customer so that the weak points and strengths of the object can be understood by everyone.

Product variants

Validate design variants including functional and flow tests:

Apart from material behavior, design also influences thermal behavior. CFD simulations can be used, for example, to reduce the temperature peaks on a printed circuit board by placing the electronic components differently (thermal management).

The efficiency of entire industrial processes can also be optimized with the help of computational fluid dynamics.

Damage analysis

Fault analysis and correction:

Untraceable damage to industrial equipment, recurring component failures, unintended damage due to overheating, and more can often be explained using CFD calculations. Damages have to be explained, repaired and avoided in the future. Especially in the prevention of further, future damage, CFD analyses provide important data for design and layout to avoid stresses in the component or overheating and to optimize cooling.

Crucial:

The right partner

Merkle & Partner has been active in the field of engineering calculation with FEM and CFD simulations for over 30 years.

In hundreds of projects each year, we make invisible physical phenomena visible, help to better understand and optimize structures and products. And deliver meaningful approaches to solutions. With added value.

Merkle CAE Solutions GmbH not only has a lot of experience. We work on the basis of the latest technologies, are involved in research projects and maintain close relationships with universities but also strategic partners from the industry. Take advantage of highly qualified know-how to advance your products and your company.