Slip Stick Simulation

Task / Calculation

The very high number of hits on our somewhat harmless video suggests that something else is often suspected behind the term slip-stick.

We will confine ourselves here to the purely technical side and say goodbye to all other interested parties who will certainly find what they are looking for on other websites.

The slip-stick effect, which is also known as the stick-slip effect, describes the jerky sliding of solid bodies moving against each other. The effect occurs as soon as the static friction is greater than the sliding friction. Depending on the material, this leads to the excitation of vibrations which are emitted as disturbing noises and/or can lead to severe wear.

In the everyday environment, the effect is experienced, for example, as "door creaking", rattling windshield wipers or squealing brakes. In industry, the unwanted stick-slip effect can be found in numerous areas, e.g. conveyor technology, vehicle construction, servo technology, linear technology and lifting technology.

By means of a slip-stick simulation, the influence of a wide variety of parameters on the development or elimination of the effect can be simulated, e.g. surface condition, contact forces, process speed, ambient temperature, friction, air humidity.

We encounter this topic more frequently when, for example, a rotatable construction made of metal (steel, aluminum, zinc) is replaced by plastic. The component is now cheaper, but it starts to squeak when twisted. The simulation shows the causes and helps to eliminate the effect by appropriate measures, as it always appears "cheap". Apart from this, components where slip-stick effects occur generally have a shorter service life. In the case of a €100,000 vehicle, it may even be a reason for a customer to withdraw from his purchase contract if the brake squeals so loudly when he comes home that the neighborhood complains.

The mathematical approach is not trivial. As shown in the video example, the simulation can be transient, i.e. time-dependent. In the case of brake squeal, there are two (complex) natural frequencies that are close to each other. Basically, there are two scenarios in which customers turn to us with this issue.

1. research into the cause of slip-stick effects occurring after a machine has been built, described as squeaking, rattling, creaking, etc.

2. in the case of new developments, where bad experiences have already been made in this respect and which one would now like to avoid already in the construction phase.

We will show you which is the most suitable approach for your problem and perform the calculations for you.

Goal / Benefit

We show you which is the most suitable approach for your problem and perform the calculations for you. This allows you to see what the causes are and what adjusting screws there are to avoid squeaks, rattles and creaks.

Video

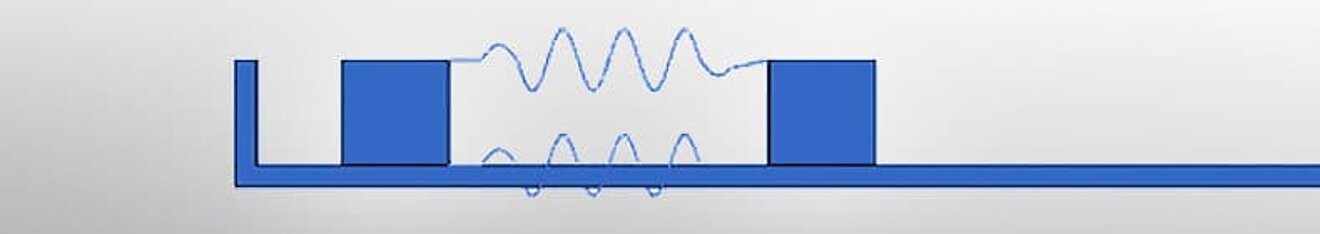

The attached video shows the effect for the simple case of two blocks connected by a spring. One block is moved and the other alternates between static and dynamic friction.

Keywords

- Acoustics

- Brake squeal

- Natural frequencies (complex)

- Sliding friction

- Static friction

- Creaking

- Squeaking

- Rattle

- Vibration

- Slip-stick