FEM - Simulation

Structural analysis and optimization

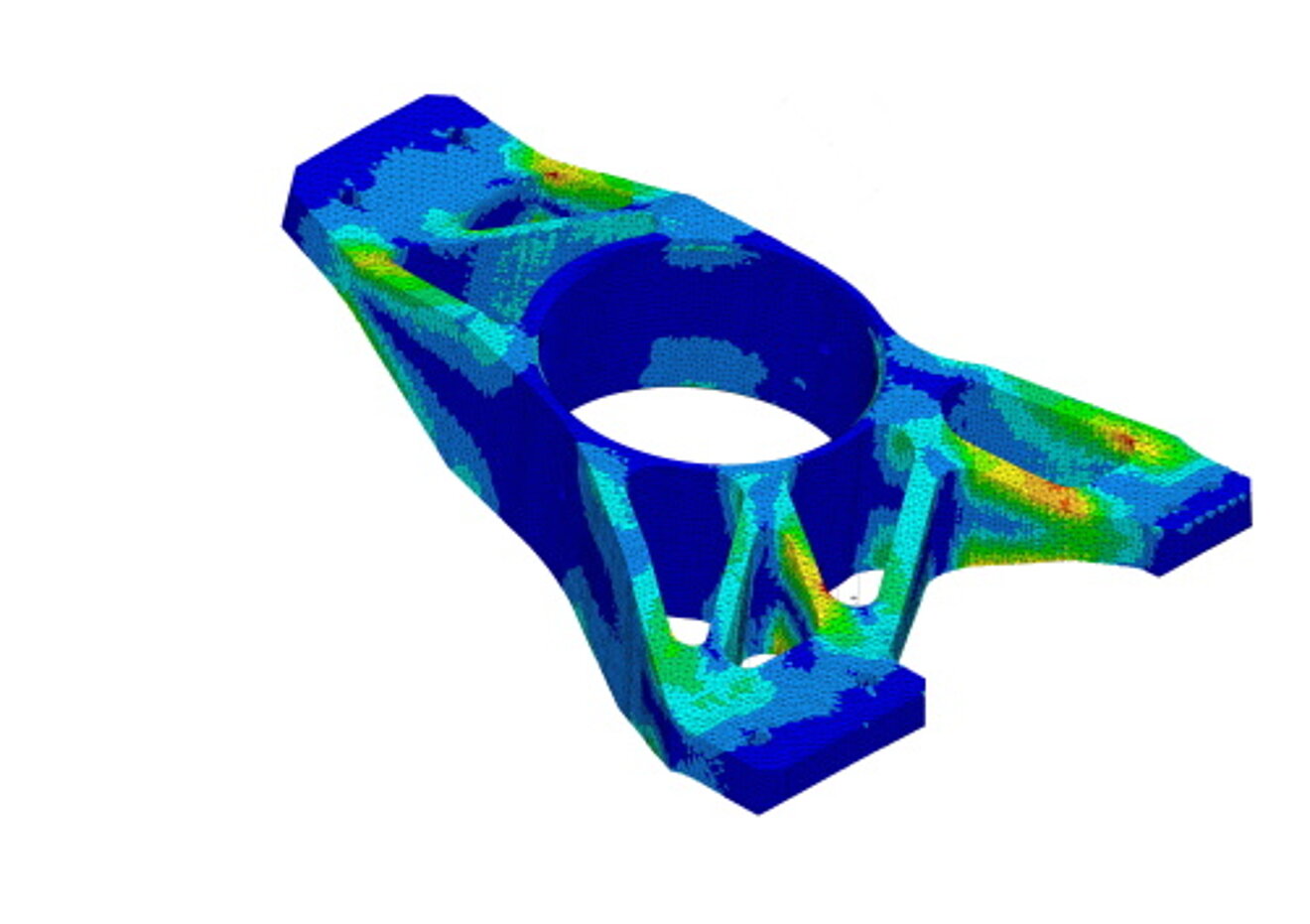

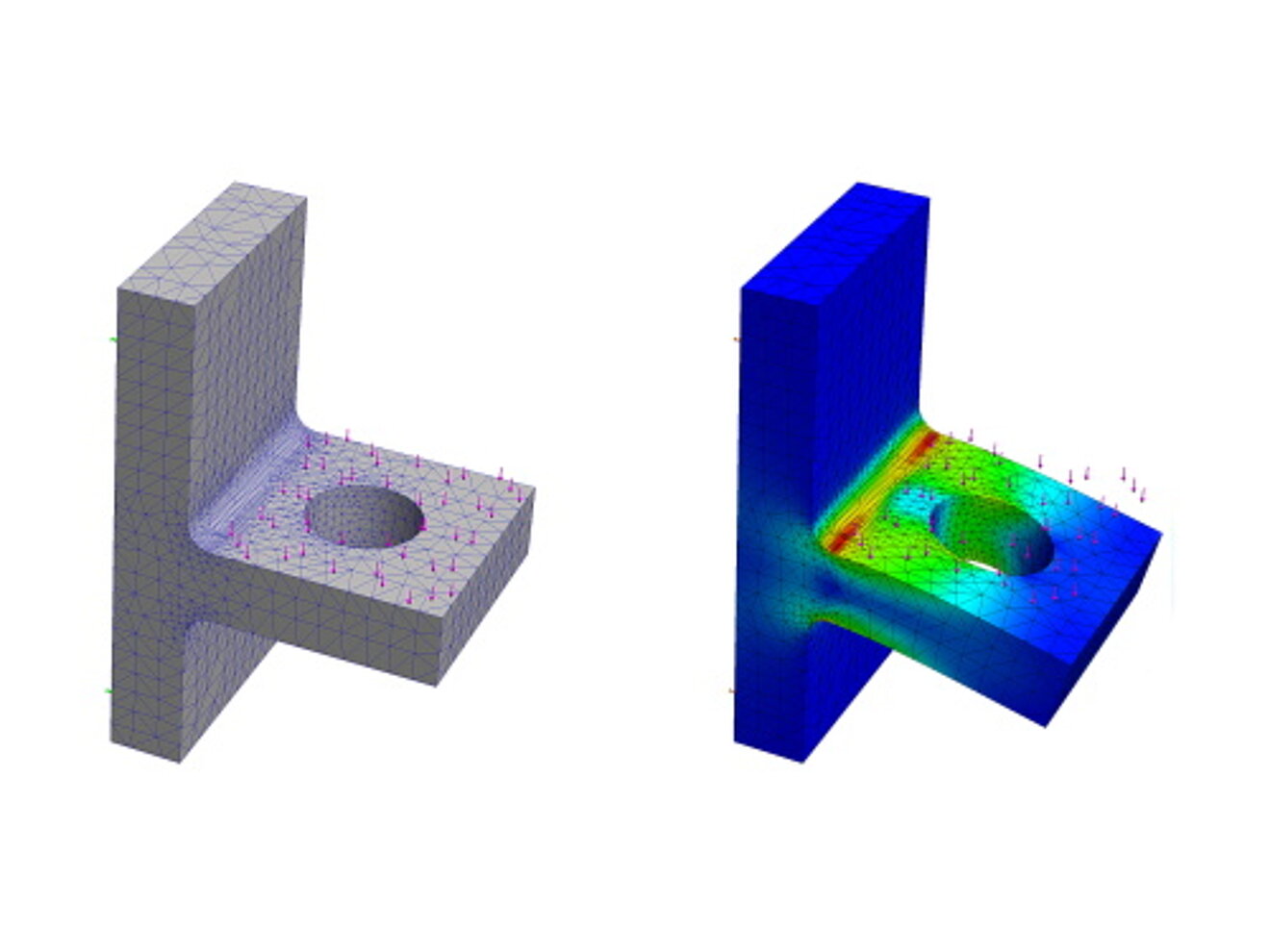

FEM simulations make the physical behavior of assemblies, components and materials visible under different boundary conditions, i.e. loads.

This is why the finite element method is so valuable for modern product development. It can be used to predict behavior, rule out damage-prone designs, optimize weight and conduct tests virtually.

With FEM calculations, you gain digital insights into your product development that would otherwise have remained physically hidden from you. This saves time and resources. At the same time, you accelerate your product development and benefit from insights that improve your product design.

FEM calculation

Your advantages

Deep understanding

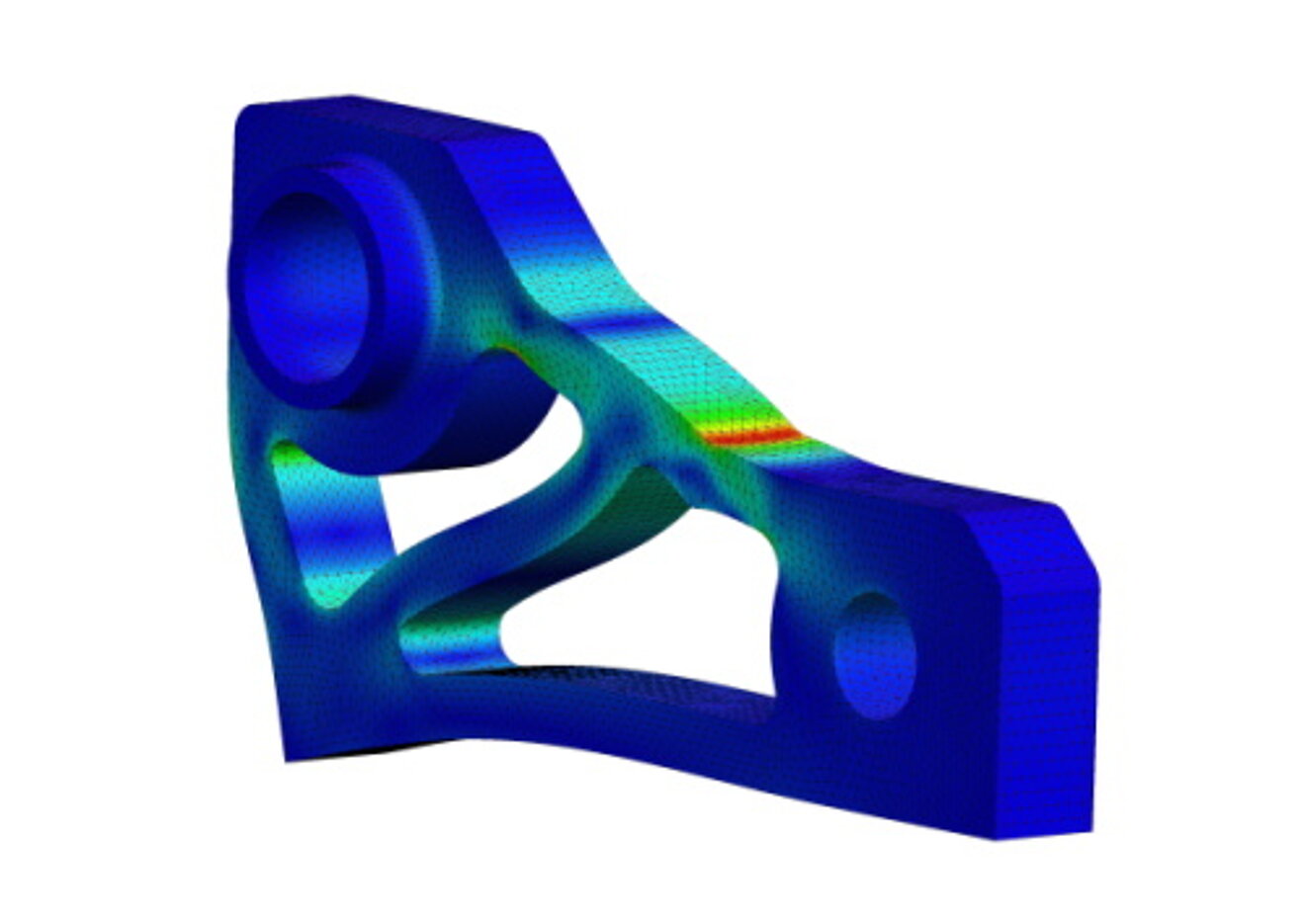

The FEM calculation results in an in-depth understanding of the structure (solid) with regard to function, vibration behavior and service life for your own product. Thus, you recognize the optimization potential of your product and have security!

Fast product variations and optimizations

FEM simulations, unlike physical prototypes, can quickly record and simulate changes. A real time advantage!

Reduction of the test effort

If the behavior of complex components is also known, the design and material can be optimally matched to the function. Tests can be reduced to the determination of the material behavior. Tests on the component can be drastically reduced and are used for the final verification, which is usually passed. Lengthy test phases are thus noticeably shortened.

Rapid readiness for series production

Damage and error analyses reveal weak points that can be optimized directly. Test times are shortened. The readiness of products for series production is accelerated.

When does FEM make sense?

Simulations via FEM calculations can be used at any point in the product development or life cycle:

Product development

For the development of stable and functional rough geometries.

To develop ideal assembly models, proof according to appropriate standards.

Function validation, manufacturing simulation, assembly simulation.

Functional tests, load tests

Product variants

Validation of design variants including functional and load tests:

Here, an FEM calculation offers you the advantage of analyzing different versions of a component via calculation models. This allows you to test designs of product variants. You can arrange assemblies differently to obtain data at a very early stage on how your designs influence stability and material behavior, for example.

Damage analysis

Error analysis and correction:

If faults and damage occur in your components during operation, the cause of which cannot be found immediately, FEM calculations provide valuable information to identify possible causes. This is to your advantage, because you can concentrate more quickly on repair options and the future avoidance of faults. We look for the weak point and support you in optimizing it. You save costs by quickly analyzing the damage.

Crucial:

The right partner

Merkle CAE Solutions GmbH has been active in the field of engineering calculation with FEM and CFD simulations for over 30 years.

In hundreds of projects each year, we make invisible physical phenomena visible, help to better understand and optimize structures and products. And deliver meaningful approaches to solutions. With added value.

Merkle CAE Solutions GmbH not only has a lot of experience. We work on the basis of the latest technologies, are involved in research projects and maintain close relationships with universities but also strategic partners from the industry. Take advantage of highly qualified know-how to advance your products and your company.