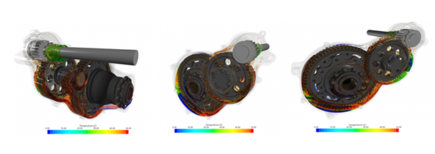

New: Simulation for gearbox oiling with temperature verification

Gear oil must not only lubricate, but also dissipate heat. Temperature influences the viscosity and flow behavior of the oil. This in turn not only influences transmission running, but also compression and the overall starting and running behavior of the engine.

"Consequently, the development and optimization of transmissions is also about optimizing temperature distribution in the components and cooling," says Stefan Merkle, managing director of Merkle & Partner GbR. "Temperature therefore has a very large influence on gearbox development, which was also repeatedly requested by our customers. Until now, this influence was in fact hardly comprehensible via simulation technologies. At least not in highly complex transmission simulations." Because in order to realistically pick up and calculate all factors, high-performance computers would have to work for months.

Merkle & Partner has taken on this problem and recently started offering an economically and temporally attractive calculation of temperature simulations in transmission lubrication. The basic assumption is that the flow in the gearbox adjusts faster than the temperature. Using this engineering approach, computing times as well as memory requirements can be reduced enormously, as co-simulations can be performed with different time scales.

"The idea was born out of a lot of experience and a certain amount of 'thinking outside the box,'" says Stefan Merkle. "Here I can look with pride at my team. Because, of course, we also got the first trial calculations behind us, refined the model and are delivering revealing results."

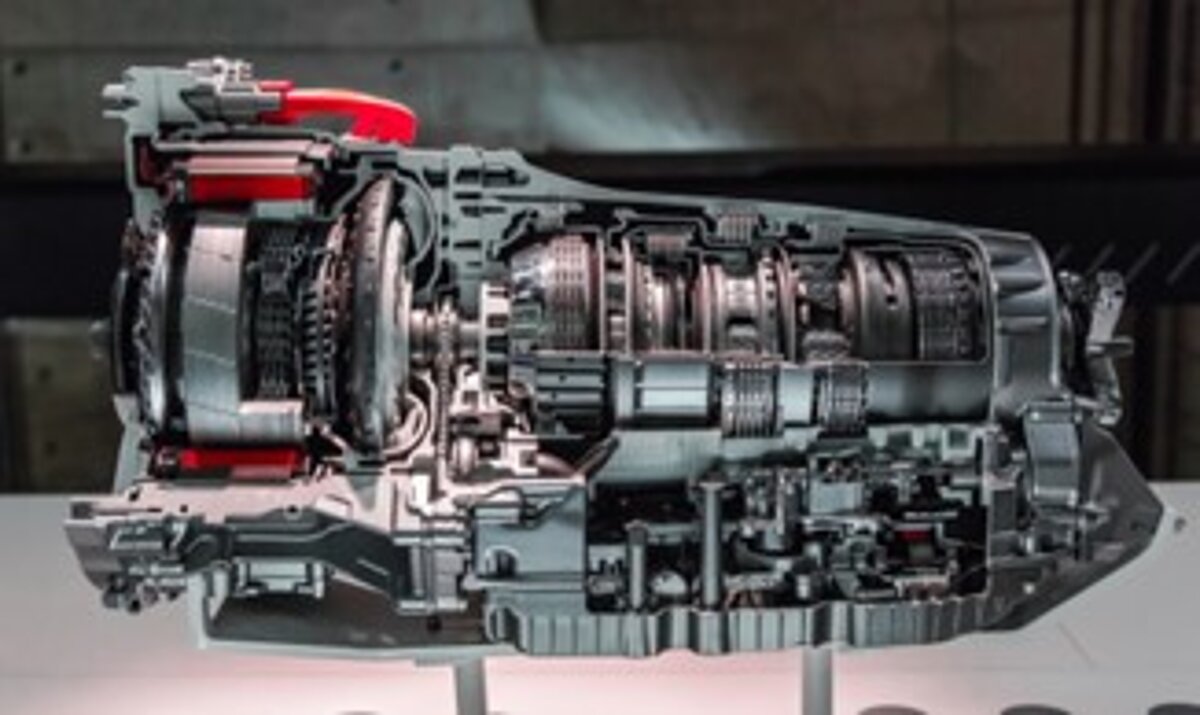

For simple types of gears, the simulation has already proven its worth. But even for highly complex structures, such as 8-speed dual-clutch transmissions, the engineers at Merkle & Partner seem to be working on solutions.

"We have been working on simulation and oil distribution in transmissions for more than ten years. In our simulation toolbox M&P ÖlSim®, an essential component that was always at the top of our customers' wish list was missing until now: the consideration of temperature. Now I can say that we have also mastered this challenge," says Stefan Merkle

For more information, see:

Gear Lubrication 3.0