Project start ROAD3D - New research project for the calculation of 3D-printed metal components

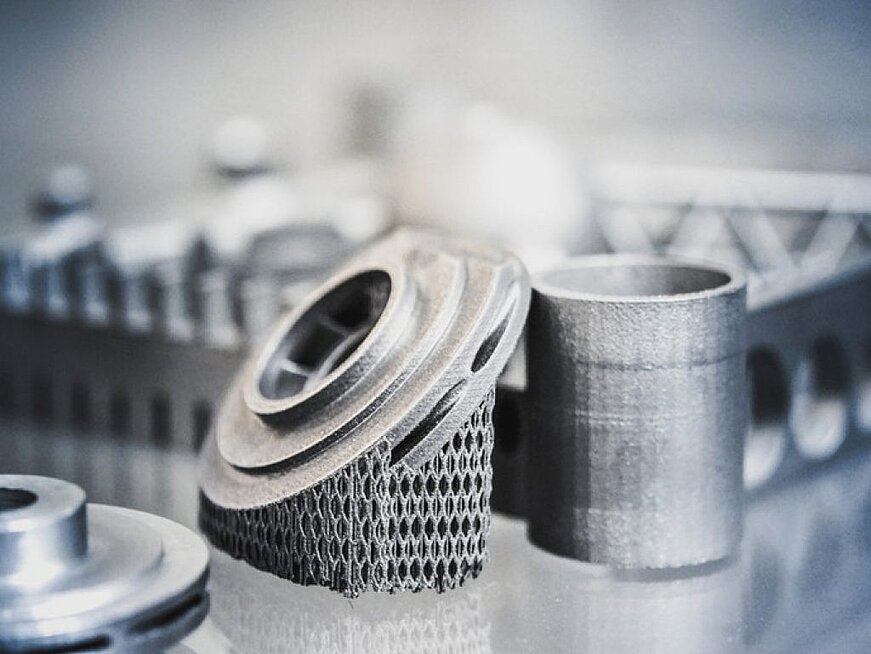

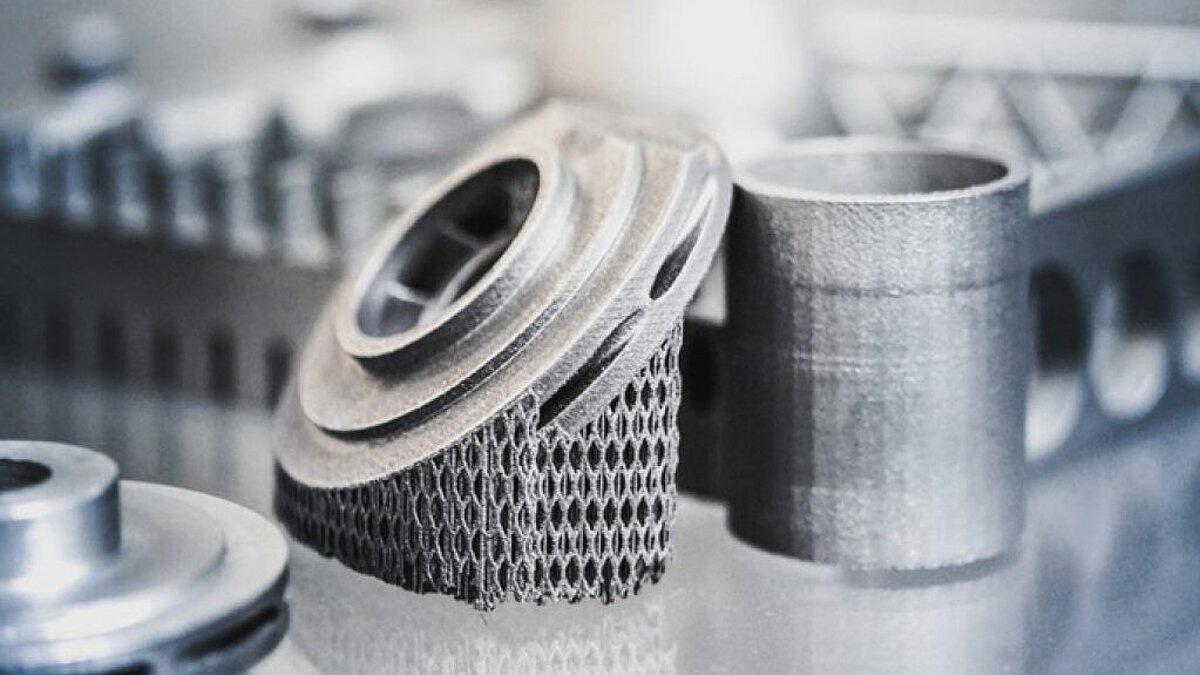

On 18.07.2019, our latest research project ROAD3D started. In cooperation with Aalen University, we want to make the design of 3D-printed components safer in a pragmatic and affordable way.

The name says what we have made our goal: ROAD3D - Robust design and dimensioning of safety-relevant components for 3D metal printing.

As a calculation service provider, we are always in the area of tension between time, money and benefit. We therefore strive to make the latest technologies and suitable development and calculation methods simpler, faster and thus also cheaper.

If you try to describe the effects of 3D printing precisely in terms of calculation and physics, you quickly arrive at software prices of 50 T€/year and calculation times of complex components in the range of weeks. This results in costs that you, as our customers, are rightly not prepared to pay.

So if physical reality is too difficult to map 1:1, what is the solution?

A semi-empirical approach, combining CT (computed tomography) methods, experimental results and simulation!

All good ideas are stolen. I worked on material transformation simulation with SYSWELD in the early 90s, but this never turned into a business model for services. Why? Too expensive and too complex. Again, the solution was simplified methods that were fast and sufficiently accurate to determine the distortion of weldments even without metallurgy.

Not everything is suitable for 3D printing (yet), but it is astonishing that printed components sometimes show considerably higher strengths than, for example, cast components made of the same material. But the question is, how much higher?

Reliable strength values, rules of thumb and empirical values? Scarce goods!

Do you have 3D-printed components that you would like to have evaluated? We would be happy to take up your topics as part of our research project.

As with our SmartSim project, our deal is hardware (a 3D-printed part) for software (strength evaluation). But hurry up. As part of the project, we have severely limited capacity. And real samples are always better than academic examples.

Or get in touch with us and tell us about your experiences and problems encountered with additively manufactured products in practice.

Please contact Dr. Maik Brehm, extension +49-7321-9343-137, email m.brehm@merkle-partner.de.

Your Stefan Merkle