Thermal simulations - when is FEM sufficient and when do you need CFD

FEM calculations are more widespread in the calculation departments of our customers than CFD calculations. Now, there are thermal tasks in particular that can be calculated both structurally with FEM and fluid mechanically with CFD.

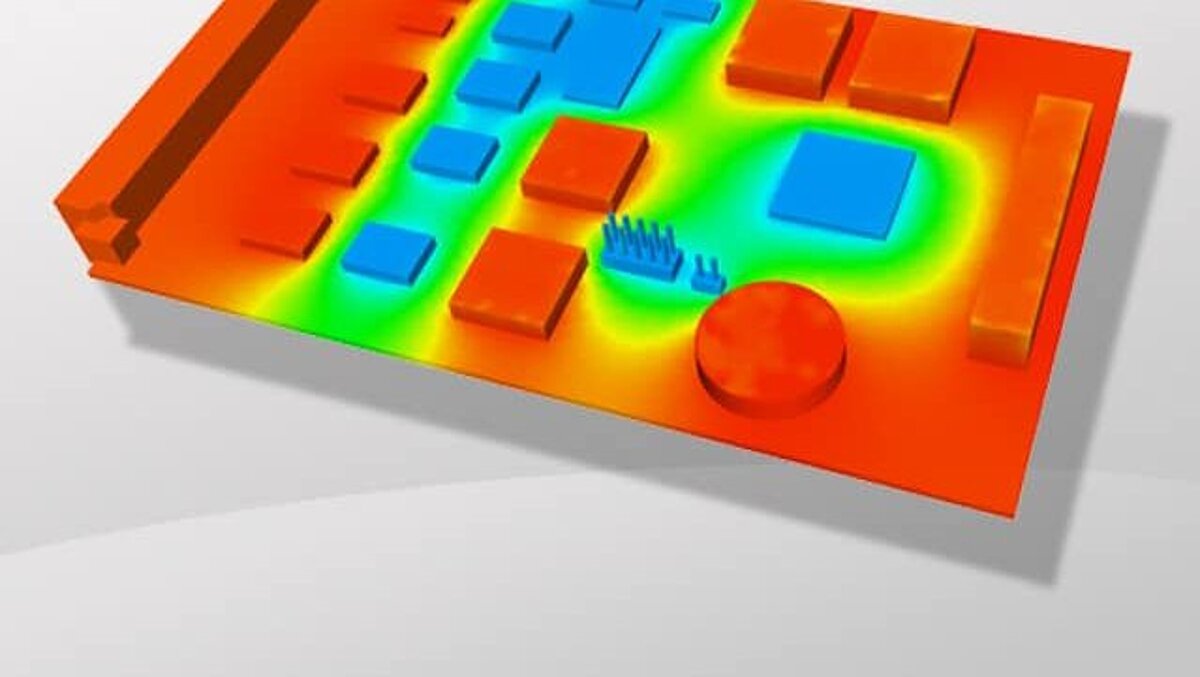

Examples are the temperature distribution in printed circuit boards, computers, electronic boxes, but also in measuring instruments and optical devices.

We often encounter the argument that the seemingly simpler and faster way via FEM, where the heat transfer values and fluid temperatures are prescribed, is perfectly adequate.

This is not entirely true, as large differences can exist, especially in high-precision optics where temperature has a significant impact on precision.

But this also plays a major role in the cooling of power supply units PSU.

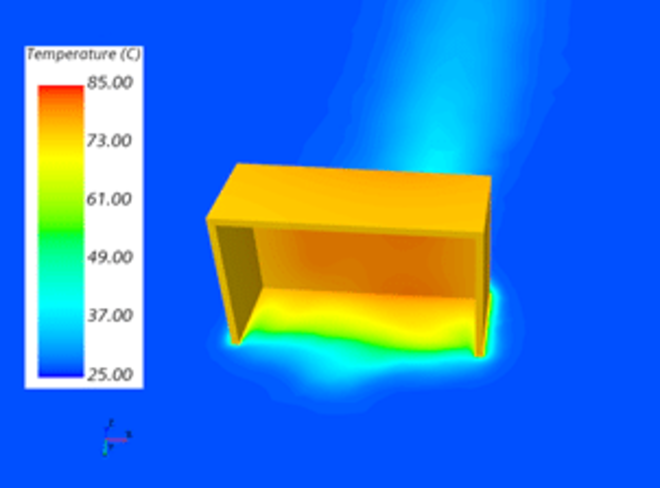

Let's just imagine a simple shoebox that is open at the bottom. If heat is generated on the upper side, it cannot simply escape from the underside. An insulating warm air cushion is formed.

The real temperatures are then higher than the temperatures calculated via FEM.

The averaged heat transfer values of the heat atlas are already no longer suitable for accurately representing the conditions - even if the inclination of the vertical wall is also taken into account.

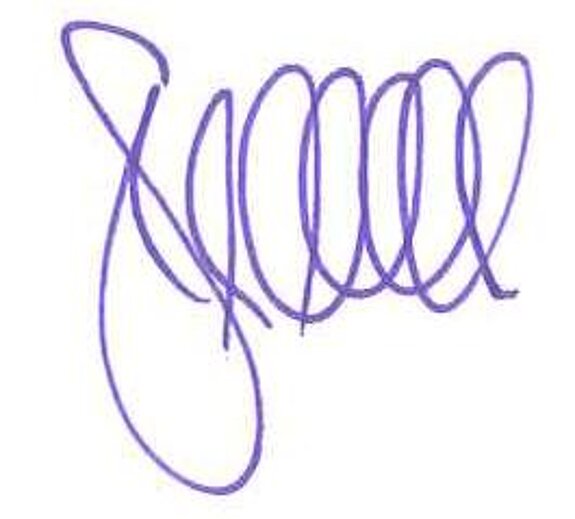

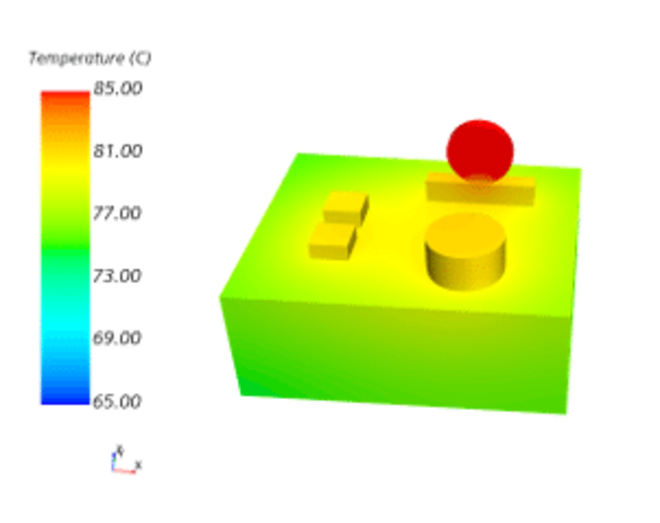

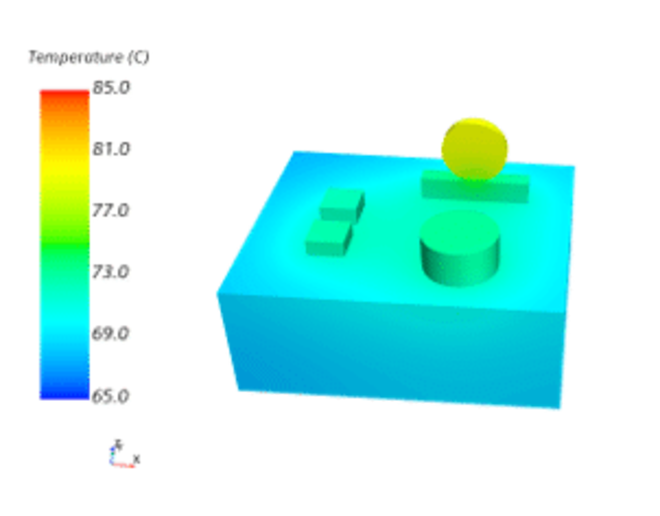

The attached pictures of an investigation of the same model with FEM as well as with CFD show considerable differences with the same scaling in the course. The maximum temperatures also differ by about 10%.

This difference can be decisive for the correct conclusions.

In the present case, the component temperatures of 87°C exceed the value of 85°C often assumed to be permissible for circuit boards, while the FEM calculation signals that everything is fine at a maximum temperature of 79°C.

Figure 3 shows how the warm air remains trapped in the shoebox and heats up. The temperatures of the air here no longer correspond to the ambient temperature of 25°C, but are much higher, at about 40-60°C.

Thus, less heat is dissipated and the component temperatures of the electronic elements rise.

Whenever a housing comes into play, this effect leads to up to 20% higher temperatures in the more accurate CFD calculation.

We know from a large number of projects when a simplified approach using the FEM is sufficient and when we have to resort to the more accurate CFD calculations. Of course, the required accuracy also plays an essential role here.

However, it is no longer the case that the CFD calculation must always be significantly more complex than the FEM calculation.

Among other things, we also have to make evaluations of the temperatures on complete vehicles and are under enormous time pressure here as well.

Accordingly, we have appropriate systems and methodologies to investigate even the most complex models quickly and efficiently.

And if an FE model is sufficient for the accuracy requirement and much faster and cheaper to calculate, we will of course calculate your thermal tasks with FEM.

This is the great advantage of a computational service provider that is at home in both simulation worlds, flow and structure.

My suggestion to you:

You send me the result of a thermal calculation via FEM together with the requirement you have for accuracy.

We evaluate for you free of charge whether we consider a calculation with FEM to be sufficient in this case.

If we are of the opinion that the accuracy you require (maximum value, spatial distribution) is exceeded, you will receive a cost estimate for the thermal analysis via CFD.

If you then agree, we will perform the CFD calculation for you.

You only pay for this CFD investigation if the CFD calculation also shows that the difference is greater than the tolerance you want.

Does this sound like a fair deal to you?

Then we look forward to your use cases.

Just send me the data with the note TestFEMCFD.

Yours Stefan Merkle