Gearbox lubrication 2.0

... how you know after just a few days whether your gearbox is sufficiently lubricated before you have built it.

The calculation of oil flow in a fast rotating gearbox is one of the most challenging tasks in computational fluid dynamics (CFD).

In a partially oil-filled gearbox, complex geometry meets complex physics and complex dynamics.

An intensive manpower requirement in geometry preparation as well as uneconomical calculation times can make the use of a simulation seem unprofitable here. Thus, modeling times and calculation times of several weeks are not economical and the results come too late in the development process.

Simulation method for calculating oil distribution in real gearboxes

Merkle & Partner has already dedicated itself intensively to this topic in 2010 and developed a simulation method that enables the calculation of oil distribution in real gearboxes in an economically profitable time.

Months became weeks, weeks became days.

During development, we focused on the following points:

- effective geometry preparation with reduced manpower and time requirements

- no limitation of the geometry, detailed flows in the bearings and bearing gaps should be mapped as well as the flow in the oil sump

- The method should be equally applicable in simple two-stage gearboxes up to 7-speed double-clutch gearboxes or planetary gearboxes

- a robust meshing method whose number of elements ensures economical calculation times

- a robust but also sufficiently accurate representation of the physics, including multiphase flow (oil and air) and rotation

Development of a similation kit

The simulation method was successively further developed in cooperation with several OEMs and first-tier suppliers and finally transferred into a special simulation kit.

The use in a multitude of transmission projects in the last 5 years confirmed the use and the simulation results of the "Merkle & Partner Öl-Sim" simulation kit.

Smoothed Particle Hydrodynamics (SPH) Method

In 2018, the previous simulation process was extended with the help of PreonLab, a CFD software based on the Smoothed Particle Hydrodynamics method (SPH).This software is developed in Freiburg by FIFTY2 Technology GmbH.

PreonLab offers an enormous time advantage compared to conventional CFD methods. The decisive advantage of this method lies in a gridless procedure, which means that only a small amount of manpower and time has to be invested in geometry preparation and meshing. The geometry can be taken from the CAD data and used directly for the simulation.

This proverbial "drag & drop" simulation method is particularly suitable at a very early stage of development. Global flow effects, such as the functionality of oil reservoirs, oil holes or guiding elements in the housing wall, can be calculated and visualized effectively and quickly.

Photorealistic representations as well as effective post-processing options are further advantages of PreonLab.

In addition to the rapid further developments of the PreonLab software, the simulation toolbox is subject to ongoing further developments and optimizations at Merkle & Partner.

For example, in 2018, we developed and verified an improved model to represent the tooth mesh. In addition, simulation parameters were optimized to minimize numerical diffusion, especially at very high speeds, and to further increase the quality of the results.

Calculation example:

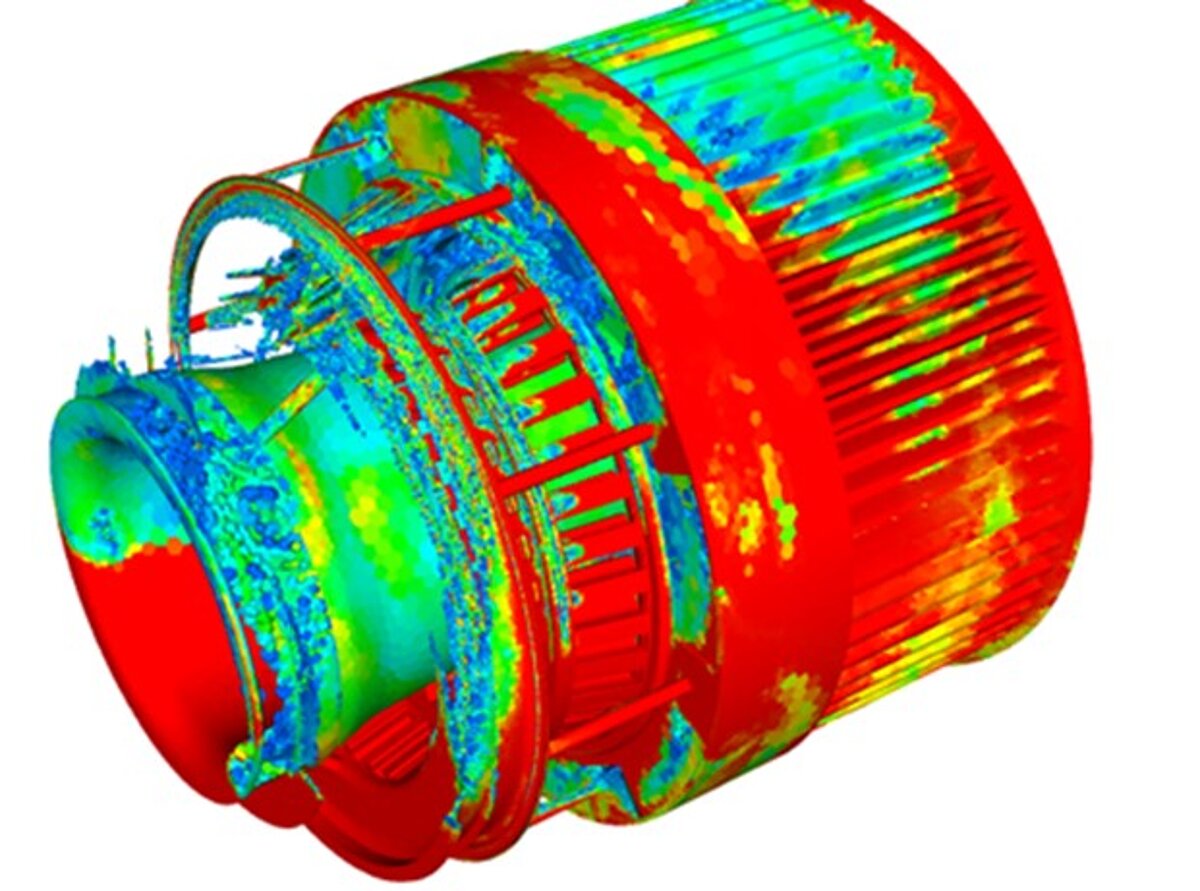

The planetary gear shown in the attached videos is a highly alienated project that we have done in-house with the "Merkle & Partner Oil Sim". The example describes the new SPH method in more detail.

The example is used to describe the new SPH method in more detail.

Task

In the planetary gearbox, oil is to be conveyed upwards from an oil sump by the planetary gears into an oil reservoir.

The operation of the collecting ribs above the planets is to be evaluated and optimized.

The project was a complete success from the customer's point of view and confirms the correctness of the assumptions we made.

Do you also want to develop your gear units faster and more efficiently? Avoid unnecessary losses in the oil sump and still have all bearings sufficiently lubricated?

We would be happy to arrange a non-binding consultation appointment or a telephone consultation with our contact person Chadi Serhan.

Phone: +49 (0)7321 9343-0

E-Mail: info@merkle-partner.de

Of course, you are also welcome to browse our website:

www.merkle-partner.de

Your Stefan Merkle