Trial vs. simulation - the never-ending story of who is right now

Since I've been involved with simulation, there's been this argument between the test engineers and the simulation engineers.

The test people claim that simulation is not accurate enough, some simulation advocates claim that in the future there will be no need for testing and everything can be backed up via simulation.

Both are fighting over what seems to be a limited pie and are afraid that the other side will steal the sausage from their bread.

Let's take a closer look at both sides, and we are already at the important topic of accuracy.

When I want to determine an error, what do I refer to?

Simulation

The real geometry of the components usually deviates from the CAD models, but this means that the geometry of the CAE calculation model is already subject to errors.

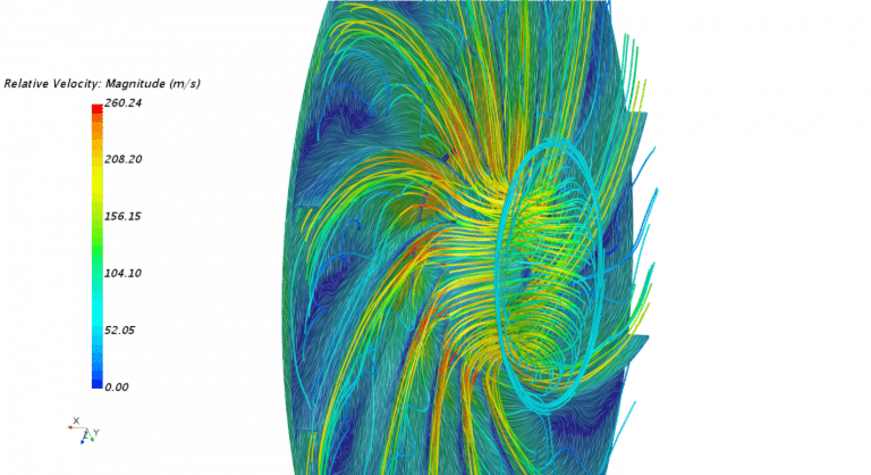

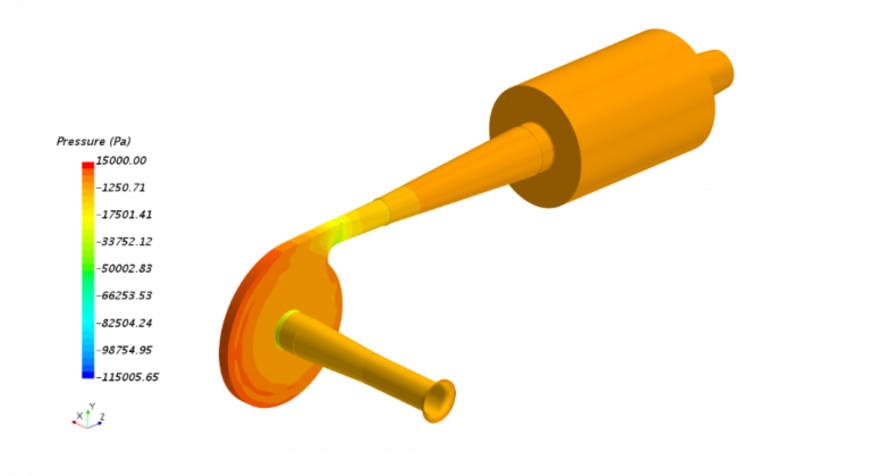

Although the physics is increasingly better represented in the CFD software systems, it is still an approximate solution. In addition, there is the influence of the boundary conditions, which are also often idealized.

Try

But the test also has its pitfalls:

The gaps of a compressor alone sometimes deviate considerably from the CAD model, but they have a serious influence on efficiency and characteristic curves. The measurements are carried out selectively, and even the determination of the volume flow is an averaged value that assumes that the flow conditions are constant across the pipe cross-section. Measurement inaccuracies and errors are also commonplace.

Discrepancies

In the case of large discrepancies, we often see that the model we examine in the calculation and the test model for the test have large deviations in the geometry alone, because other components were installed, e.g. a different diffuser was used in the test.

But discrepancies between test and simulation do not only occur in the area of flow.

In finite element calculations, the material behavior is already an assumption that was determined at some point on the basis of (erroneous?) tests. The material characteristics scatter with the batch used and are only minimum values.

Magnitude of the errors

My many years of experience show me that the errors are of about the same order of magnitude in both the test and the simulation. 3-5% is a good value in both cases.

Both the test and the calculation have their strengths and weaknesses.

In both cases we also assume a scenario, which is also only a conservative(?) assumption for the use of the components in reality.

The problem - communication

The problem is that test engineers and calculation engineers speak different languages.

We therefore prefer, as simulation engineers, to also look at the test setup in reality if possible.

Often, as in a specific case, the test carrier of an electronic system, which we assumed in our simulation model to be an aluminum die-cast part (information from the CAD model), turns out to be a milled part made of pure aluminum. Unfortunately, the thermal conductivities differ here by a factor of 2, so it is no wonder that there is a difference of up to 40% in the peak temperature between simulation and test.

Conclusion:

Back to the initial question: Both are right.

Experiment and simulation complement each other. Both are error-prone, both have their strengths and weaknesses.

The experiment often serves as a proof, there is no way around it.

Simulation is faster and cheaper for variants and optimizations, offers a better insight into physics ... and needs material data and fluid data coming from the experiment.

If we use testing and simulation in the right place and ensure that both sides exchange information without bias, we can develop new, safe components faster and more efficiently.

Your Stefan Merkle

PS: Are you curious? Find out in a non-binding, free and personal conversation how we can also support you in the development of your products.

Please get in touch with us.