Common design mistakes and how to avoid them: Mistake #1

The consequences of serious design errors drive many a company to ruin.

A rule of thumb says that costs increase by a factor of 10 each time component changes are required at the various development stages (planning, production, testing, customer use).

So really expensive damage only occurs at your customer's site.

It is all the more astonishing that the same mistakes are made again and again in the design and development departments during damage analyses. If you know these, you can already take care to avoid them during the development of components and assemblies.

Damage in this context is not just when components break, but when they no longer fulfill the promised properties either immediately or over time.

Damage analysis has always been my hobbyhorse - finding out what causes components to fail to do what the designing engineers thought they would.

In the process, I made an astonishing discovery: In not a single one of several hundred cases of damage in over 26 years of my professional career was the cause an unfortunate chain of circumstances such as.

- poor material

- slightly higher loads

- poorly executed welds

- too large tolerances

These did play a role and broke the camel's back.

But as a rule, there was only one main cause!

And this main cause was a design fault which could have been recognized as such.

These errors occur over and over again and can be categorized into a few groups.

In future blogs and in special webinars, I will discuss individual design errors that I have encountered again and again.

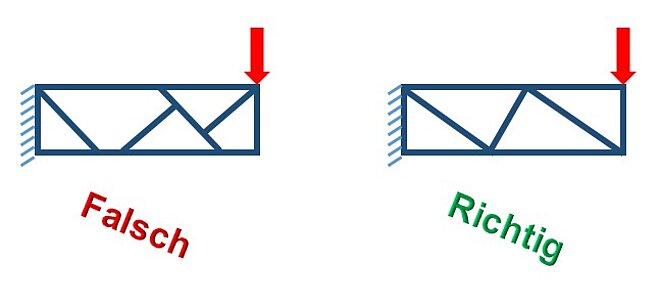

Error #1: Wrong position of ribs

When ribbing components, the ribs should be stressed in tension and compression, not in bending.

The adjacent figure shows what can go wrong here:

In the left figure, ribs do not run onto common nodes. Ribs end on other ribs and thus load them in bending.

If ribs are arranged incorrectly, the influence on stiffness is lower, but at the points where the force flow is interrupted or diverted, unnecessarily high stresses occur due to bending.

Stress concentrations lead to cracks starting from these points.

If the basic principle is understood, it is very easy to see that these considerations can also be applied to machine frames, frame structures, etc.

Conclusion: Wrong or bad ribbing uses less and fails faster.

I look forward to your questions

.