Common design mistakes and how to avoid them #2

![[Translate to English:] Baum-steifigkeitssprünge [Translate to English:] Baum-steifigkeitssprünge](/fileadmin/_processed_/3/b/csm_Baum-Steifigkeitsspruenge-16x8_aa8ca54f8c.jpg)

This is a continuation of my blog on common construction mistakes.

Mistake #2: Stiffness jumps

Nature shows us, for example in trees, that stability and strength under the load of their own weight, wind, snow and rain is achieved by soft transitions.

Starting from a massive trunk, a tree becomes progressively slimmer. The areas with the highest loads have the largest cross-sections, the light leaves are only supported by thin branches.

The load transfer into the soil takes place through an interconnection of roots, which mostly have the same dimension as the crown.

There are no large jumps in stiffness, the transitions are rather smooth.

As a result, the stress gradient in the trunk and branches is uniform.

In contrast, stiffness jumps, which are hardly ever found in nature, lead to local stress peaks from which cracks originate under changing loads.

Construction errors that I frequently encounter in damage cases are thin components that are connected to comparatively thick components without soft transitions.

Typical design flaws are outlined below:

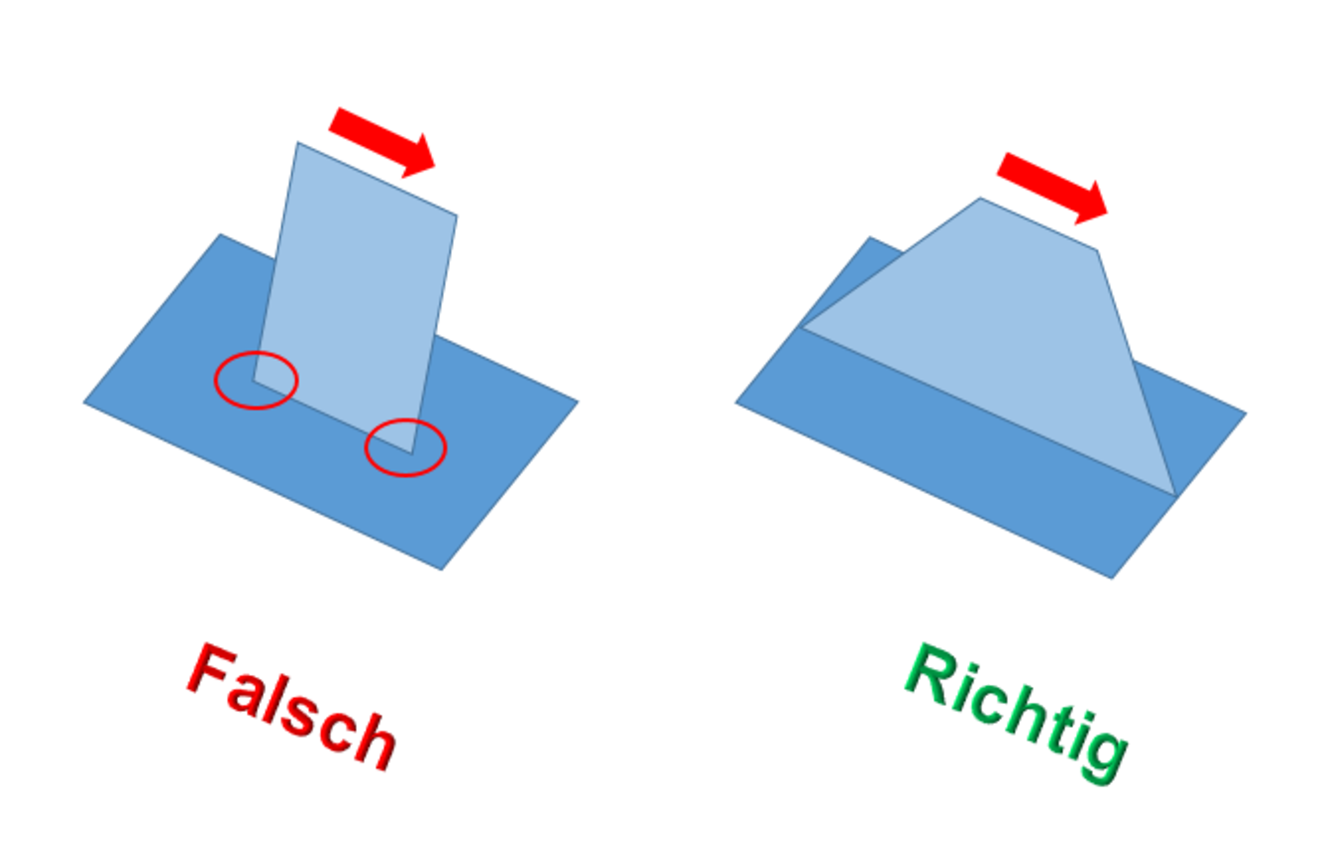

Welded constructions with metal sheets

Sheets that are attached to other sheets in the middle via welded joints and carry forces have stiffness jumps at the marked points and thus unnecessary stress peaks (circled in red).

This can be prevented by levelling out the connecting plates.

However, stiffness jumps can also be found wherever solid components are connected to comparatively soft components and transfer loads.

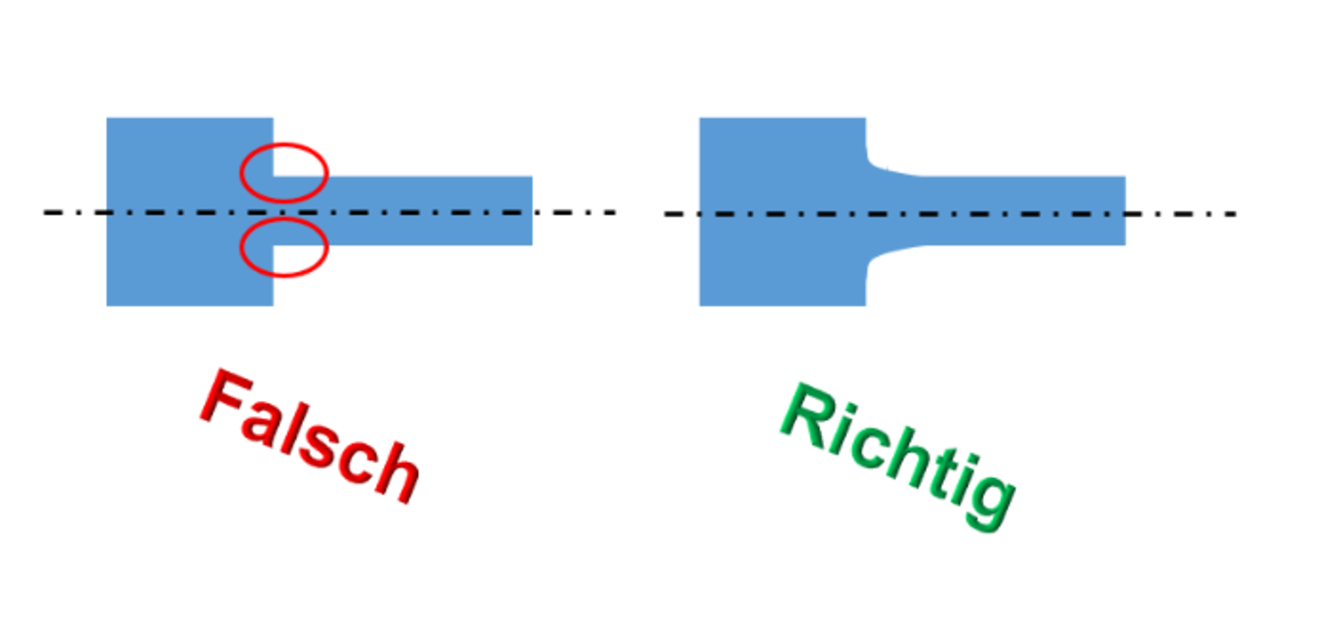

Shafts and rotors with large diameter jumps

In the case of broken shafts and rotors, the cause of the damage is often that the fillet radii or, if necessary, the shaft recess is too small.

This can be avoided by adjusting the diameters, possibly also by intermediate grading and generous fillets or recesses.

Conclusion: Stiffness jumps lead to high stress peaks at the transition points, which quickly cause cracks under changing loads.

The ideal body from the point of view of strength has the same stress level everywhere during loading.

In contrast, stresses at the edges of interference fits are rather uncritical, since these are essentially compressive stresses. In this case, plasticization occurs at the edge, which does not affect the fatigue strength. As a result, the stress is made uniform.

I look forward to your questions 🙂