Luminaire cooling

![[Translate to English:] merkle-partner-leuchten-kuehlung [Translate to English:] merkle-partner-leuchten-kuehlung](/fileadmin/_processed_/a/2/csm_header-kuehlung-leuchten_2dbf7c8f89.jpg)

Introduction

Modern luminaires such as high-efficiency LED lamps convert up to 80% of the electrical power into heat. To dissipate this heat, either heat sinks or a cooling air flow through an electrically operated fan are required. However, there are often conflicts here between the modern design and the available installation space.

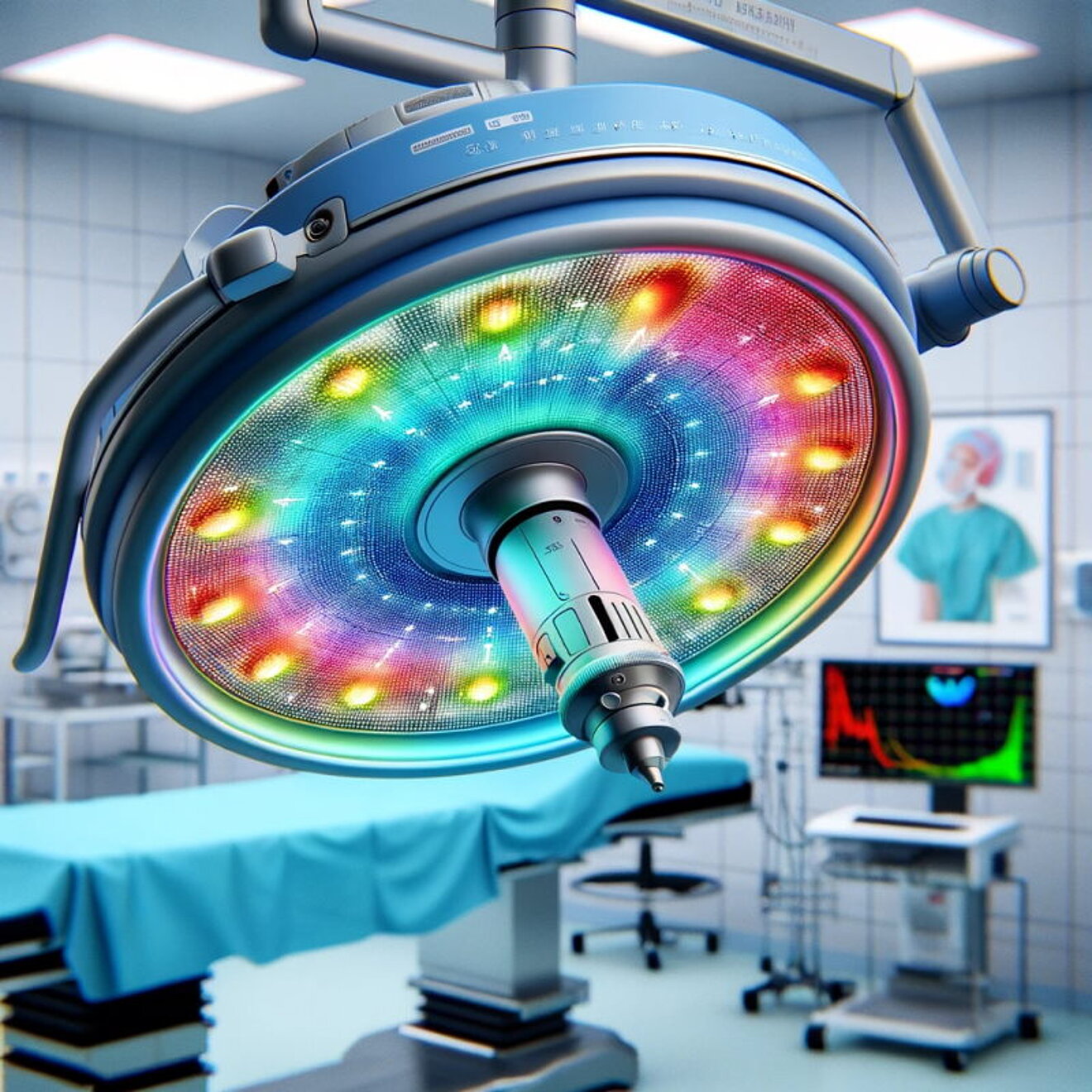

In the medical sector in particular, e.g. in operating theaters, the use of high-power LED lamps poses major technical challenges. These lamps generate considerable amounts of heat and effective cooling is crucial to extend their service life and ensure optimum performance. The cooling system to be developed must dissipate the heat efficiently without compromising the sterile conditions in the operating room. Exposed cooling fins should be avoided as they are difficult to clean.

Computational Fluid Dynamics (CFD), or flow simulation, plays a central role here. CFD simulations allow engineers to virtually test and analyze different design and operating conditions. By modeling the air flows and temperature distributions, we can identify the best configuration for the cooling system, ensuring that the LEDs are cooled effectively while maintaining air quality and sterile conditions in the operating room.

In addition, the lifetime and performance of LED lamps is highly dependent on their operating temperature. Efficient thermal design, including effective cooling, is therefore crucial. CFD simulations support this by helping to ensure that the lamps are operated within their optimal temperature ranges.

Task and calculation

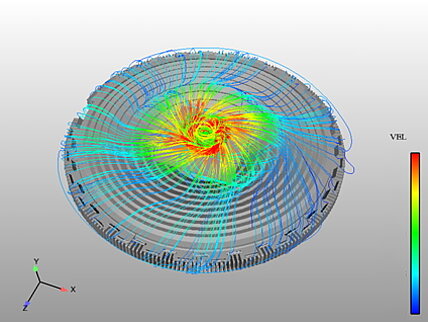

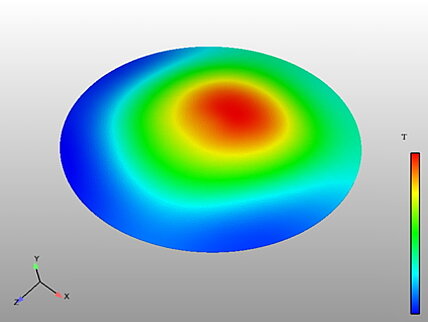

In this project for a manufacturer of operating theater lights, we were able to determine the critical load situations for the initial model using various tilted positions of the operating theater lamp and identify weak points in the temperature distribution in the PCB carrier and the PCBs.

Some areas of the LED circuit boards showed excessively high temperatures and local heat pockets formed.

Optimization

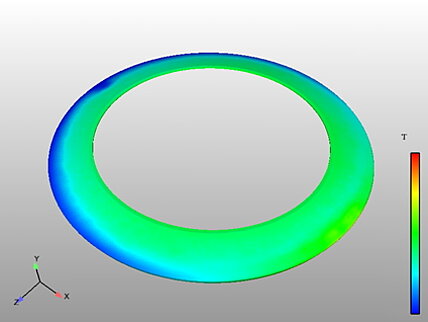

The air flow inside the housing through the fan had to be increased by design and the air routing optimized on the basis of several variant studies to such an extent that hot spots and temperature peaks could be avoided.

Results

The optimization measures with the help of the flow simulation made it possible to achieve sufficient and uniform cooling of the entire operating lamp and thus significantly increase the service life of the LEDs.

Summary

CFD simulation (Computational Fluid Dynamics) is a crucial tool for successful thermal management in the development of surgical lights, especially for modern LED-based systems. All relevant heat transfer effects such as free convection under gravitational acceleration, forced convection, heat conduction and radiation can be taken into account in the simulation.

The simulation helps to control the temperature even with different lamp positions and to avoid local overheating of the circuit board and the PCB carrier, thereby increasing the service life of the lights.