Centrifuges - everything revolves around divorce

No, this blog article is not about separation issues, where lighter women are separated from their usually heavier men, although thematic similarities cannot be denied. This is more about material separation.

Whether it's a salad spinner or a laboratory centrifuge, if you want to separate lettuce from water or emulsions or mixtures, you just have to spin the whole thing fast enough. The denser medium collects on the outside and the lighter material on the inside. That is the basic principle of a centrifuge.

There are other possibilities, but they are less effective:

If, for example, you let a mixture of water and oil stand long enough, the lighter liquid, i.e. the oil, floats on top due to gravity and the heavier water sinks to the bottom. But that takes time.

This should be somewhat faster on Jupiter than on Earth, because the gravity there is higher by a factor of 2.53. The Sun's gravity is even higher, at 27.94 times that of Earth. The gravitational pull on the sun is even higher, at 27.94 times the acceleration due to gravity. But both are far away and the sun in particular is too hot.

In contrast, let's look at a modern high-performance centrifuge.

A centrifuge uses the centrifugal force that occurs during a rotation, which also corresponds to an acceleration. Modern centrifuges can achieve up to 1,000 times the acceleration due to gravity. This value, often referred to as the centrifugal force, makes the gravitational forces of Jupiter and the sun pale with envy.

What is separated?

What substances now have to be separated in a laboratory?

In a laboratory centrifuge, this is often blood, where the red and white blood cells are separated from the blood plasma. But centrifuges are also used to isolate DNA.

Chemistry laboratories also cannot do without centrifuges, and large centrifuges are also used in the enrichment of uranium. Also in Iran.

A look at the risk

Since laboratory centrifuges often have speeds in excess of 18,000 rpm, there is a certain risk if excessive imbalances or even fractures occur within the centrifuges.

The circumferential speeds are almost 100 m/s with a radius of 50 mm and a speed of 18,000 rpm. The flow forces at work here are enormous; just imagine what happens if you reach your hand towards the open window of your car at a speed of 360 km/h. The majority of cars are designed for such speeds. Most cars, however, are not suitable for such an experiment due to a lack of everything (from the engine to the chassis to the tyres).

In operation

There are many things you can do wrong when operating a centrifuge in the laboratory.

You can load the centrifuge incorrectly, causing it to be unbalanced and creating excessive imbalances. The rotor may not be mounted properly or the wrong bottles or tubes may be used. The load can be too high or the rotor is used for too long. Or one has forgotten to put the plug into the socket.

All this can be avoided by following the appropriate instructions and observing them.

Konstruktion und Entwicklung

But what about the construction and design of a centrifuge?

When developing a centrifuge, the simulation questions are different:

What happens, for example, if a rotor breaks? Do fragments escape to the outside or is containment guaranteed? What does the entire housing do when it breaks? Does the construction remain stationary or does it jump around uncontrollably?

Are the rotating components sufficiently dimensioned? Are they fatigue-proof or does e.g. the rotor have to be replaced after a certain time?

Are resonances caused by the speed or also by imbalances? What are the natural frequencies of the centrifuge? Are critical frequencies passed through quickly or is it possible that there are no resonances in the entire speed range?

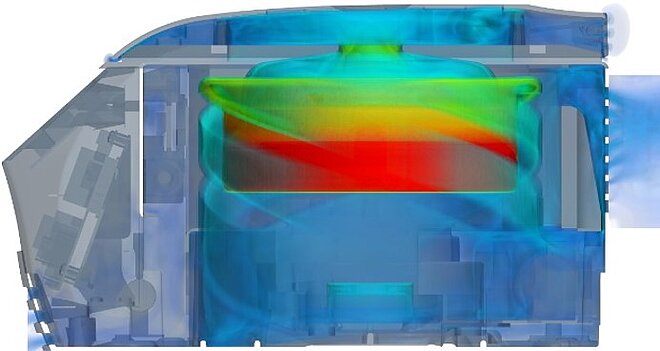

What are the flow conditions in the centrifuge? How loud are the noises and why? Are there temperature differences in cooled centrifuges and if so, how high are they? What drive power does the centrifuge need to overcome the flow forces?

Here, simulation can help to optimise centrifuges so that higher and higher speeds are possible, efficiency is optimised, oscillations and vibrations are small, centrifuges become quieter (a classic flow or CFD topic) and sufficient safety is provided in the event of rotor breakage.

The design of the bearings and the decoupling of vibrations by means of rubber bearings are also topics that can be considered via simulation with FEM.

We are happy to support you in answering such questions with our many years of unique know-how in the field of simulations.

Please feel free to contact us without obligation, we look forward to hearing from you.

Your Stefan Merkle

PS: In the spirit of digitalisation, you are also welcome to arrange your desired appointment directly with your preferred partner via www.merkle-partner.de/en/contact. If you don't know who that is, we'll find the right contact for you. After all, Germany does not have to continue to successfully defend its rear position in digitalisation for the next few years.