Simulation in fuel cells since 2006

What is often forgotten today in our very ideologically driven times is the role of energy density. The energy density indicates how much energy you can store per kg in an energy storage device. Energy density plays a major role in the evaluation of hydrogen as an energy storage medium and the fuel cell as a direct conversion of hydrogen into electrical energy.

Energy density

The unit in which energy density is measured is MJ/kg.

Figure 1 opposite shows the energy density for various energy sources in ascending order (see also Wikipedia).

The history of technical developments from the wind turbine to the steam engine and the internal combustion engine has so far always been in the direction of higher energy and power densities. The higher the energy density, the more complex and demanding the conversion into technical products.

Hydrogen has a higher energy density than petrol and diesel, so more energy can be stored in 1 kg of hydrogen than in 1 kg of petrol. In 1 kg of hydrogen, 120 MJ/kg of energy can be stored, in a litre of diesel 40 MJ/kg and in a Li-ion battery only 0.5 MJ/kg.

It is therefore technologically more difficult and demanding to build a fuel cell vehicle than a purely battery-powered vehicle (BEV). On the other hand, it is more powerful and more compact. The technological difficulties to be solved, which are reflected in the price, are higher than for a BEV. But this also means that copying is more difficult (market entry barrier). Germany is predestined for the development of such high technologies, but regularly sabotages itself when it comes to marketing them sensibly and in the long term.

Energy and power density are also development drivers in other areas. My first car phone, with which I could "only" make phone calls, weighed 11 kg at the time. Today, an I-Phone weighs about 200 grams and, in addition to making phone calls, contains the computing power of a modern PC with numerous apps, including a navigation system, translator, video player and much more.

This principle can also be found in Darwin. If you just compare the -zig tonnes and the food requirements of the Tyrannosaurus Rex with a very manageable brain with the performance of the brain of a modern human being... although, sometimes a bad example!

But the trend is clear: it is always going towards more performance in less space.

Table of energy density

| Stoff/System | gravimetrische Energiedichte MJ/kg | volumetrische Energie-dichte MJ/l |

|---|---|---|

| NdFeB- und SmCo-Magnete | 0,00 | |

| Elektrolytkondensator | 0,00 | |

| Doppelschicht-Kondensator | 0,01 | |

| Bleiakkumulator | 0,11 | 0,25 |

| Adenosintriphosphat (ATP) | 0,13 | |

| Schwungradspeicherung mit CFK | 0,18 | |

| Kohle-Zink-Batterie | 0,23 | 0,54 |

| NiCd-Akku | 0,25 | |

| Silberoxid-Zink-Zelle (Silberoxid-Zelle) | 0,27 | 0,98 |

| NiMH-Akku | 0,28 | |

| Li-Titanat-Akku | 0,32 | |

| Schmelzenergie Eis | 0,33 | |

| Nickel-Zink-Akkumulator | 0,43 | |

| Zebra-Batterie (Natrium-Nickelchlorid) | 0,43 | |

| Alkali-Mangan-Batterie | 0,45 | 1,26 |

| Druckluft (ohne Tank) | 0,46 | 0,14 |

| Li-Polymer-Akku | 0,54 | |

| Natrium-Schwefel-Akkumulator | 0,45 | |

| Li-Ionen-Akku | 0,65 | 0,70-1,80 |

| Wasserstoff (inkl. Hydridtank) | 1,19 | |

| Zink-Luft-Batterie | 1,20 | |

| Lithium-Luft-Akkumulator | 1,60 | |

| Kondensationswärme des Wassers | 2,26 | |

| Lithium-Thionylchlorid-Batterie | 2,34 | |

| Thermit | 4 | 18,40 |

| Trinitrotoluol (TNT) | 4,60 | 6,92 |

| Aluminium-Luft-Batterie | 4,70 | |

| stärkste Sprengstoffe | 7 | |

| Restmüll | 8-11 | |

| Braunkohle | 11,30 | |

| Wasserstoff (flüssig, gebunden an LOHC) | 13,20 | 10,40 |

| Zucker | 16,70 | |

| Holz (lufttrocken) | 16,80 | |

| Stroh und Klärschlamm (trocken) | 17 | |

| Holzpellets und Holzbriketts | 18 | |

| Braunkohle (Brikett) | 19,60 | |

| Methanol | 19,70 | 15,60 |

| Ammoniak (flüssig) | 22,50 | 15,30 |

| Ethanol | 26,70 | 21,10 |

| Altreifen | 29,50 | |

| Silicium | 32,60 | 75,90 |

| Kohlenstoff | 32,80 | 74,20 |

| Steinkohle | 34 | |

| Benzin und Rohöl | 40-42 | 29-32 |

| Diesel und Heizöl leicht | 42,80-43 | 35-36 |

| Propan (flüssig) | 46,30 | 23,40 |

| Methan (Hauptbestandteil von Erdgas) | 50 | 0,03 |

| Wasserstoff 1 Bar (ohne Tank) | 120 | 0,01 |

| Wasserstoff 700 Bar (ohne Tank) | 120 | 5,60 |

| Flüssiger Wasserstoff (ohne Tank) | 120 | 10,10 |

| Atomarer Wasserstoff | 216 | |

| Radioisotopengenerator | 5,00 103 | |

| Kernspaltung Natururan (0,72 % 235U) | 6,48 105 | |

| Abbrand (Kerntechnik) | 3,80 107 | |

| Zerfall des freien Neutrons | 7,46 107 | |

| Kernspaltung 235U | 7,94 107 | 1,50 109 |

| Kernspaltung 232Th | 7,94 107 | 9,30 109 |

| Kernfusion (Kernwaffe, Kernfusionsreaktor) | 3,00 108 | |

| Proton-Proton-Reaktion | 6,27 108 | |

| vollständige Umwandlung von Masse in Energie | 8,98 1010 |

Fuel cell vs. battery

Let's look at a fuel cell vehicle from this point of view. At least the energy storage can be built much more compactly than in a pure battery vehicle with the same energy. The energy density is also higher compared to a combustion engine.

It can be refuelled more quickly and has a much greater range. Minus points are certainly the high price, among other things.

And water can freeze in winter!

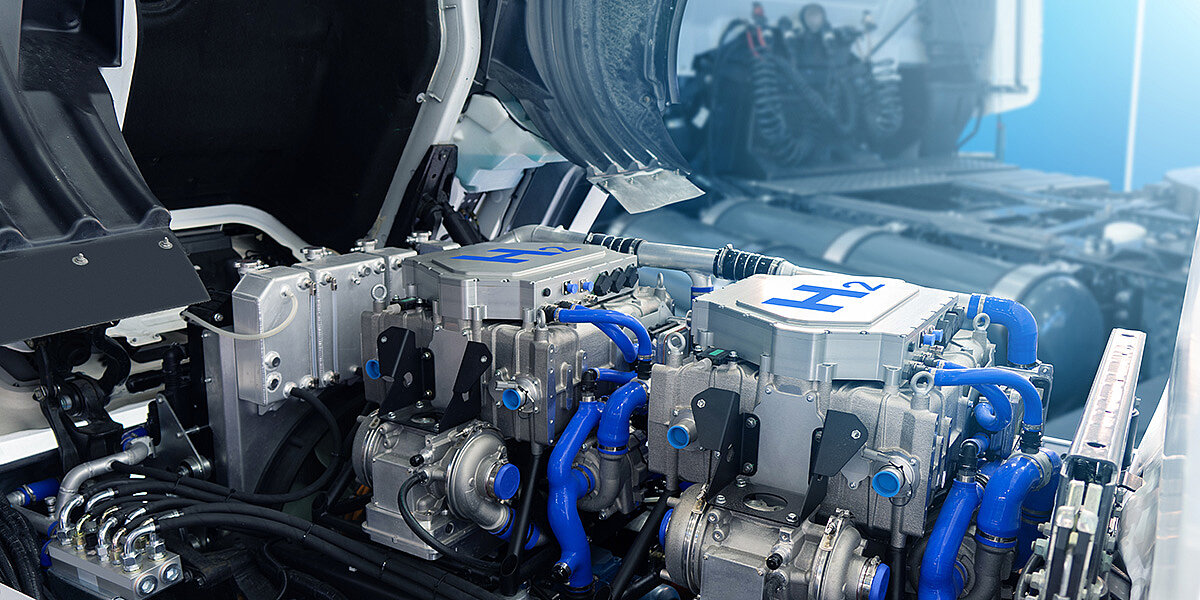

What does a fuel cell drive consist of?

A fuel cell drive requires a tank for hydrogen, a small, powerful battery, the fuel cell to generate electricity, an electric drive train, electric motors and various auxiliary units such as intercoolers and humidifiers.

A fuel cell drive has to dissipate about the same amount of heat to the environment as an internal combustion engine, where about 1/3 of the power goes into the radiator, 1/3 can be used for propulsion, and 1/3 is dissipated to the environment via the exhaust gas. However, with fuel cell propulsion, the temperature difference to the environment is much smaller, which makes heat dissipation physically more difficult.

How does a fuel cell work?

The heart of a fuel cell consists of two electrodes: the anode and the cathode. They are separated from each other by an electrolyte that is impermeable to gases. Each of the electrodes is coated with a catalyst, for example made of nickel or platinum. Hydrogen (H₂) is fed to the anode, oxygen (O₂) to the cathode. On the anode side, the hydrogen is oxidised to protons by releasing electrons. The electrons flow from the anode to the cathode via an external circuit. Thus, current flows. The protons diffuse through the electrolyte to the cathode. At the cathode, water (H₂O) is formed from the protons and electrons together with the oxygen supplied from the ambient air. A fuel cell thus continuously produces electrical energy, thermal energy and water.

Compared to the battery, the fuel cell has the advantage that continuous operation is possible for a very long time without intermediate electrical charging. Vehicles powered by fuel cells can carry large quantities of hydrogen without increasing their weight significantly.

Let's take a closer look at the 4 main components of a fuel cell drive and the associated tasks:

Hydrogen tank

We assume here a liquid tank with a 700 bar under standard conditions. The ambient temperature can vary from -40°C to 85°C, which means that the pressure in the tank can rise up to 875 bar.

The tanks must be light and yet safe for mobile applications, which is why tanks wound from GRP and CFRP are used here.

When filling the tank, the high pressures cause the dispenser to ice up.

A tank under such high pressure is a small bomb. Due to the high safety requirements and the not entirely simple manufacturing process, the tanks must therefore be extensively tested.

Fuel cell stack

All cells of the stack should be flowed through as evenly as possible due to the efficiency and temperature (equal distribution). The temperature distribution must be as homogeneous as possible.

Tightness, even over several years, is a high requirement.

Humidifier

The air for the fuel cell must be very clean. No dust particles may get into the stack. The air must have a defined humidity.

Intercooler

In the intercooler, high heat flows must be dissipated to the environment at low temperature differences.

Battery and drivetrain

The battery in a fuel cell vehicle is much smaller than in a BEV and serves as a buffer to absorb power peaks. The electric motors must be cooled efficiently.

Modelling and simulation

The challenge for modelling and simulation is that several physical areas (electrochemistry, thermomechanics, structural mechanics and fluid mechanics) have to be considered for the fuel cell over different levels of detail (behaviour of the entire vehicle in traffic down to the behaviour of an individual component).

In the case of overall system simulations, e.g. the entire vehicle, it is rather the behaviour that is important, whereas in the case of components it is rather individual effects. In modelling, we speak of 0D, 1D or 3D models. The more comprehensive the system to be considered, the simpler the modelling approach for the large number of components. For example, a fuel cell can be calculated as a transient 3D model in which the temperature fields are described as a function of time, by the mean temperature along the flow (1D) or only by the mean temperature of the entire stack (0D).

Calculation examples

The above gives rise to a large number of questions that can be investigated and answered with the help of simulation, structural simulation FEM or flow simulation CFD.

Here are a few examples that we have calculated over the past 16 years in the field of fuel cells:

- Sealing behaviour of the stack under the influence of temperature

- Uniform distribution of the incident flow of the stack

- Electrochemical behaviour of the stack and comparison of temperatures with test results

- Behaviour of flanges, hydrogen lines and gaskets with regard to creep behaviour and leak tightness over time with different cycles

- Development of creep models based on material measurements

- Simulation of the humidification process via flow simulation with multiphase models

- Recalculation and optimisation of the heat exchangers

- Behaviour of the stack foils during pressing

- Comparison of transport mechanisms based on 1-D simulation results

- Optimisation of H2 corrugated tubes with regard to buckling safety

- Investigation of fuel cell stacks with straps in the event of a crash.

- Development of end plates made of plastic instead of metal

- Investigation of complete tank systems made of wound GRP tanks

- Investigation of H2 truck and H2 trailer with regard to structure and crash

- Design of test chambers for hydrogen cylinders

- and much more.

As you can see, over the last 16 years we have already dealt with a wide range of fuel cell simulation topics when the subject of hydrogen was still in its infancy.

Take advantage of our many years of experience in the simulation of fuel cells and components. We look forward to receiving your tasks.

Yours Stefan Merkle