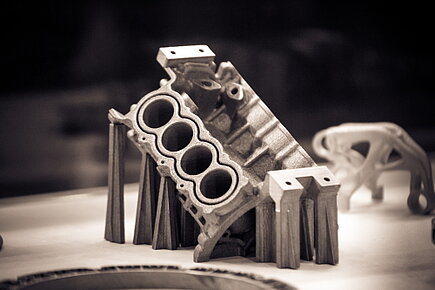

Additive Manufacturing Workshop

The results to date from the research work carried out as part of Road3D are already providing valuable information for well thought-out design and manufacturing in 3D printing. Aalen University and Merkle & Partner will process this knowledge sequentially until the end of 2021 and discuss it with interested parties in a series of lectures.

The topic of the kick-off workshop, scheduled for 11.11.21, will primarily be anisotropies. From the formation of thermal and mechanical anisotropies during 3D printing to process simulation and strength evaluation, the latest findings will be communicated and discussed.

"With the Road3D research project in cooperation with Aalen University, we are answering important questions step by step regarding the precision and strength verification of additively manufactured components. The project consistently gives us new insights and approaches, which we would like to convey to other experts as part of the workshop series. An important contribution to the discussion for further development in professional 3D printing," says Dipl.-Ing. (TU) Stefan Merkle, Managing Director of Merkle & Partner GbR.

Links Workshop Additive Workshop

Preliminary agenda and more information at:

https://www.merkle-partner.de/de/events/workshop-additive-fertigung/

Registration at: