Calculate prostheses individually in the future

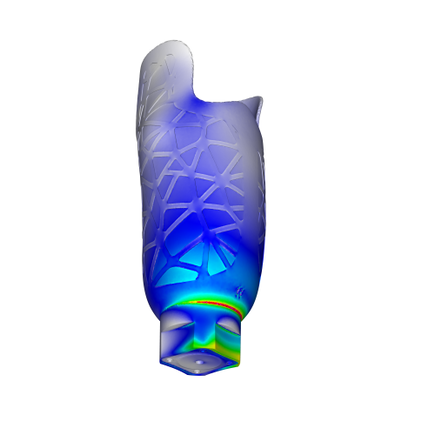

Around 90 % of prostheses in the medical technology sector are still conventionally manufactured by hand by orthopedic technicians. Simulation calculations can be used to identify stresses, strains and pressure points in prostheses in advance.

3D printers are used for around 10% of modern prostheses. However, the design is not based on simulation technologies, but purely geometric based on scanned data of the residual limb. Wall thicknesses and ribbing are designed by feel. If prostheses break, they are reinforced based on experience. This is expensive fun for health insurers, not to mention for the owner of the prosthesis, who depends on proper function.

Today's technologies have long been able to optimize the prosthesis for an MRI-measured residual limb with bone, muscle and tissue until the contact pressure reaches a minimum over multiple loading scenarios (standing, walking, jumping, bending, etc.). Unfortunately, these cases are still too expensive for widespread use in medical technology.

Using approximate values via FEM methods, however, critical zones can be evaluated and reinforced. In this way, prostheses can be designed with greater engineering precision. According to Merkle & Partner, this process could even be largely automated, if necessary by combining it with AI processes. The cost savings from the extended service life alone should amortize the required effort for larger quantities. That's what makes simulation technologies so valuable - and not just for medical technology.

"With one of our research projects, ROAD3D, we are looking at the tolerable stresses of 3D-printed components. In another research topic, we are dealing with the simulation of the human body or parts of it. Optimal conditions, therefore, for the right know-how," says Dipl.-Ing. (TU) Stefan Merkle, managing director of Merkle & Partner GbR. "Currently, projects in the field of medical technology are already being implemented. I am convinced that we will be able to provide more valuable support here in the future."