Damage case?

We support you in the event of damage

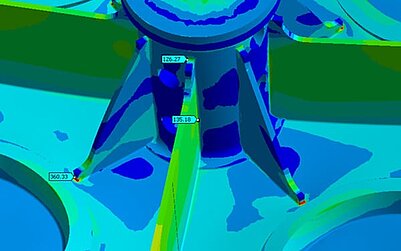

According to our experience, the main field of application of FE analyses is shifting with increasing acceptance from the field of failure analysis to the field of design or construction. However, damage analysis is still a classical application of FEM and a main field of activity of Merkle & Partner.

If components fail within the promised service life, high costs are incurred due to the replacement of the component itself, consequential damage, as well as loss of production or recall actions. A large number of these damages would have been detectable by the early use of numerical simulations in the design or construction phase. For this reason, the prevention of the damage is to be preferred according to the saying "prevention is better than cure".

Use our damage analysis!

Damage analysis of components and machines

Despite all the care taken in the development process of structures and components, the occurrence of damage cannot always be ruled out. Often, the cause is effects that were not even considered during the design phase.

The analysis of the damage is often a long process, which requires knowledge of the basic physical processes, but also a lot of experience in the field of damage analysis and a targeted approach.

Merkle und Partner, with its nearly 30 years of experience in damage analysis of various assemblies and components, will be happy to support you in the very demanding subject of damage analysis.

With trend-setting methods of optimization combined with modern CAE tools of FEM and CFD, we are able not only to determine the cause of damage by means of appropriate simulations, but also to offer proposals for optimization with subsequent verification from a single source.

![[Translate to English:] Merkle Partner Schadensanalyse [Translate to English:] Merkle Partner Schadensanalyse](/fileadmin/_processed_/d/d/csm_merkle_schadensanalyse_slider1_947c774a45.jpg)

![[Translate to English:] Merkle Partner Schadensanalyse [Translate to English:] Merkle Partner Schadensanalyse](/fileadmin/_processed_/f/9/csm_merkle_schadensanalyse_slider2_f31c2cc4ee.jpg)

Your advantage - we accompany the entire process!

- Detailed damage analysis and determination of the cause of damage using exclusion methods

- Simulation of damage development with modern CAE software

- Investigation and evaluation of repair measures

- Optimization of the structure for redesign

- Strength verification of the optimized structure

Avoid further and unnecessary costs in case of damage by a professional approach with MERKLE & PARTNER, a very experienced and efficient partner, and thus regain the confidence of your customers!

Use cases of the damage analysis

Damage examination of a dryer

![[Translate to English:] Merkle Partner Trockner [Translate to English:] Merkle Partner Trockner](/fileadmin/_processed_/d/f/csm_merkle_fem2_0956f20f5c.jpg)

The weld seams on the bottom of a dryer cracked at regular intervals and had to be extensively rewelded. The cause was high thermomechanical stresses when the plant was started up. Computational verification showed that the permissible stresses were exceeded by a factor of 3. Repair concepts using gusset plates were evaluated. The drum bottom was completely redesigned and optimized by MERKLE & PARTNER so that the permissible stresses in the weld seam could be complied with.

Damage examination of a dryer

Cracks occurred at the axle connection of a dryer. A mathematical explanation, which corresponded to the crack pattern, could only lie in the rotating bending. However, the stresses here were within the permissible range. After corresponding inquiries with the operator, we were able to determine that the dryer had been completely filled with water for cleaning purposes and had been running for several days. This load case was never considered and showed impermissibly high stresses. By avoiding the critical operating condition, the repaired condition could continue to be operated until a new dryer was manufactured.

Ground contact

![[Translate to English:] Merkle Partner Erdungskontakt [Translate to English:] Merkle Partner Erdungskontakt](/fileadmin/_processed_/9/1/csm_merkle_fem3_91b65ba338.jpg)

Fractures occurred in the grounding contacts of rail vehicles. The cause was natural resonances of the fastening. It was possible to take constructive measures so that the natural frequencies are in a non-critical range.

Fields of application

- Collection of information on the origin of the damage

- Definition of boundary conditions and loads

- Recalculation of the component

- Explanation of the damage

- Suggestions for damage prevention

- Component optimization