Explosion protection and explosion pressure shock resistance

Introduction

In apparatus and plant engineering, explosions can occur when processing certain media such as gases, vapours and media. The risk assessment or hazard analysis must ensure that the equipment is designed accordingly. This is referred to as explosion pressure resistant equipment or explosion pressure shock resistant equipment.

Standards that regulate this in detail include DIN EN 14460 or ATEX. These also describe how constructive protective measures can be taken in the event of explosions in order to avoid overloading the entire system. Bursting discs and pressure relief valves are to be mentioned here. However, the standards also describe how the mathematical verification must be carried out.

Typical components are, for example, filters, conveyors and screw conveyors, tanks, silos, etc.

A typical application is a wood dust explosion in a filter housing.

Tasks / Calculation

Different standards deal with explosion pressure resistance and explosion pressure shock resistance.

According to VDI 3673 under chapter 2.4.3 Explosion pressure shock resistance, containers and equipment must be constructed in such a way that they can withstand the expected explosion pressure without bursting. However, permanent deformations are permissible.

According to VDI 2263, the 2 % proof stress can be used for austenitic steels because of the higher deformation and hardening capacity. If this is not known, a value of the 1 % proof stress increased by 10 % can be used instead.

Technical guidelines for tanks (TRT 006 - explosion pressure shock resistance) assume that a tank is pressure shock resistant if it can withstand an explosion inside without rupturing.

At an initial pressure of 1 bar, an explosive mixture of 8 % ethylene with air has the highest explosion pressure of 9.7 bar absolute.

A tank is considered to be explosion pressure shock resistant if, in an experimental test on a prototype, an explosion with the above mixture is endured under atmospheric initial conditions without rupturing. The test can also be carried out with water, whereby 1.3 times the highest explosion pressure must be endured without rupturing.

Standards also allow the verification to be carried out either by means of a test or by means of a suitable calculation method such as a non-linear finite element calculation (FEM).

If one takes a closer look at the individual regulations, the dynamics of a pressure surge are taken into account via a load increase factor of 1.3 (test by water compared to explosion).

The computational verification now consists of describing the test described in the respective standard by means of an elastoplastic FEM calculation, in which the failure (rupture) is described by a failure criterion in the form of the plastic strain.

The mathematical verification of a container, tank or housing is fulfilled if the specified, permissible plastic strain is not exceeded at any point.

Here, the maximum pressure is statically applied to an FEM model with elastoplastic material behaviour and the strain is evaluated.

Connecting elements such as screws and weld seams can also be modelled and evaluated here.

If the mathematical verification cannot be carried out or if there was even a failure in tests, the question is how to optimise the design.

Often, an adjustment is made via the sheet thickness of the critical areas.

If one is more interested in how a pressure wave develops over time during an explosion, this is a task that can be answered using transient flow simulations CFD. For example, the local and temporal course of the pressure surge can be simulated in order to dimension bursting discs.

Further simulation methods are used in the design and verification of test chambers, which can also depict the bursting of test specimens with water or compressed air, as well as describe the impact of the fragments and the water on the walls. If you are interested in this, you will find further information under the heading Containment and test chamber on our homepage.

Particularly in large plants, physical explosion tests can only be carried out with very high test costs and a high risk, which is why computational tests, as described here and regularly carried out by us, are increasingly being used.

Another major advantage of simulation is that optimisations can be carried out much faster and in a more targeted manner in the event of component failure.

h schneller und gezielter durchführen lassen.

Project example

Verification of the explosion pressure shock resistance of a filter housing at an overpressure of 0.2 bar.

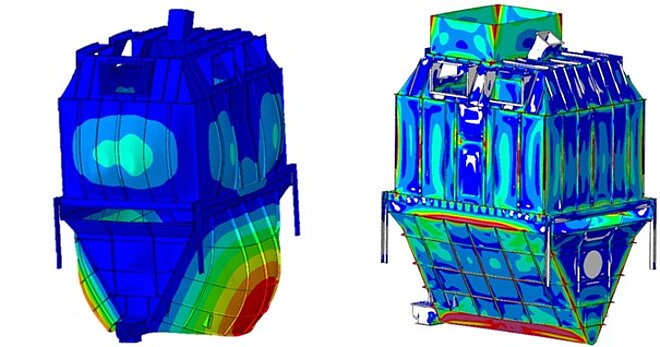

The example described below shows a filter housing for which the explosion pressure shock resistance has been verified by calculation.

In the initial version, there was still high plastic strain or even failure (tearing) in the physical tests, especially in the lower area of the filter.

In the picture on the left, the calculated verification could not be carried out with the initial wall thickness. By increasing the wall thickness, the mathematical verification could be carried out and the subsequent test successfully passed.

Summary and outlook

The verification of explosion pressure shock resistance can increasingly be carried out using virtual calculation models, which are also being recognised more and more often by conservative testing bodies such as the TÜV.

The standards generally permit verification with suitable calculation methods.

Benefit

The recalculation is much faster and cheaper than a physical test.

Norms and standards

The following standards are used:

- Pressure Vessel Ordinance - "Ordinance on Pressure Vessels, Pressurised Gas Vessels and Filling Installations".

- DIN EN 14460 - "Explosion-proof equipment".

- ATEX 2014/34/EU - "Directive for equipment and protective systems intended for use in potentially explosive atmospheres".

- DIN EN 13445 - "Unfired pressure vessels" for pressure vessels, heat exchangers and fittings

- TRT 006 - "Technical guidelines of tanks, explosion pressure shock resistance".

Keywords

- Container

- Rupture discs

- Pressure vessel

- Elastoplastic material behaviour

- Explosion

- Explosion puncture resistance

- Explosion proof devices

- Explosion resistance

- FEM calculation

- Filter

- Non-linear FEM calculation

- Silo

- Dust explosion

- Tank

- Deflagration