Hydrogen refueling as a risk factor

Hydrogen is one of the beacons of hope for renewable energies. For this technology to be used on a large scale, refueling must be safe, among other things, because it is precisely then that the tanks are highly stressed. Using CFD simulations, Merkle CAE Solutions can visualize optimal refueling processes.

Hydrogen tanks are high-pressure tanks, which - used incorrectly - can also become small or larger bombs. This is precisely why there are standards with clear specifications as to which temperature and pressure limits must be adhered to, so that the end user can also use such a tank without danger.

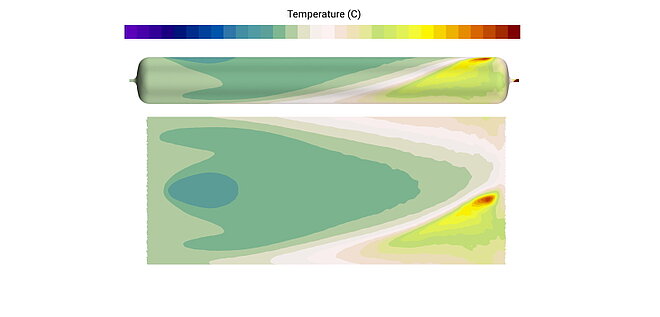

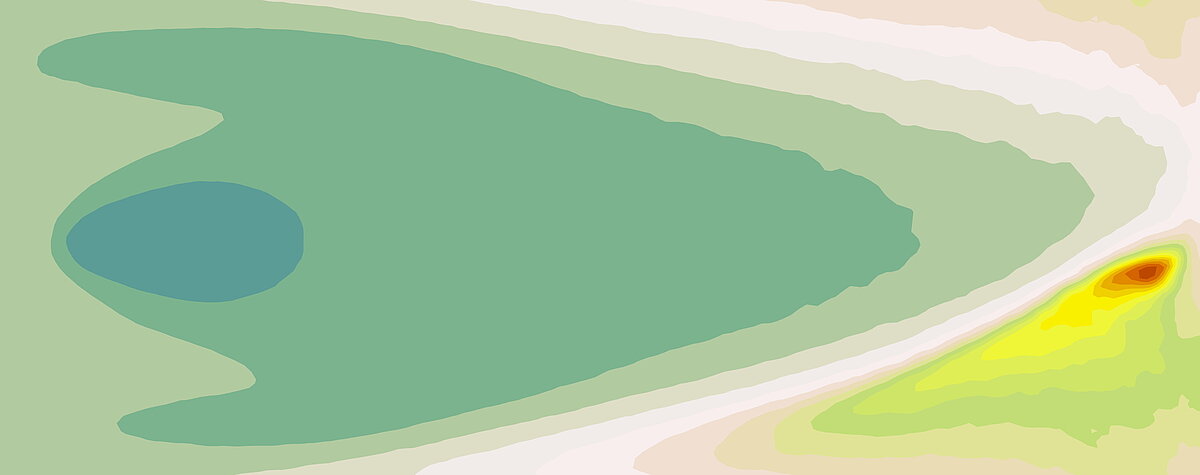

The permissible temperatures are max. 85°C, the maximum pressure of 125% of the nominal pressure must not be exceeded. These specifications are particularly important for the refueling process, which should take place as quickly as possible. Hydrogen is refueled under high pressure. The high inflow velocities, especially in the initial phase, increase the temperature of the hydrogen. In addition, during axial, i.e. direct, straight-line refueling, the hydrogen collides with the opposite wall of the tank. The temperatures are high, the material heats up locally, expands and the thermomechanical stresses in the tank increase, which can lead to damage of the tank, possibly uncontrolled up to explosion.

Refueling should therefore be carried out at an oblique angle in order to achieve short refueling times. But how can this angle be optimally adjusted so that temperature peaks are avoided as far as possible?

This question arises again and again for cars, trucks, gas stations, ships or airplanes and offers a classic application for a transient flow analysis, i.e. one that is considered over time.

"Physically as well as computationally, CFD simulation for hydrogen refueling is challenging because the time steps must be smaller than 1x10-5 seconds due to the high flow velocities. However, the refueling process itself goes on for 30 seconds or longer," said Stefan Merkle, managing partner of Merkle CAE Solutions GmbH. "In order to make correct statements about the optimization of tank processes, physical framework conditions, logical extrapolations, but also economic calculation times have to be considered. Be it fluid mechanical topics with CFD or structural mechanical topics with FEM simulation - in the field of hydrogen technologies Merkle CAE Solutions builds on relevant know-how."

Translated with www.DeepL.com/Translator (free version)