Merkle & Partner: Making future technologies predictable

3D printing for safety-critical components is still immature. There are no standards for solid proof of strength or uniform testing. These hurdles must be overcome for the actual industrialization of the process. The cooperation between Merkle & Partner and Aalen University is intended to enable appropriate standardization.

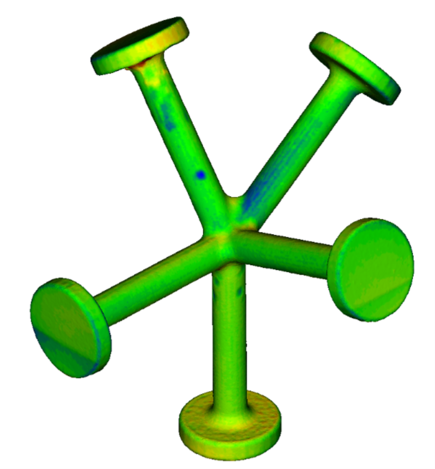

In the process, a wide variety of components are simulated, printed and tested in real life. Using a wide variety of software tools, it can already be seen that the ROAD3D cooperation has developed simulation methods that have reproduced internal physical flaws and stresses in the printed components in line with reality.

"In 3D printing, we work with the layer-by-layer fusion of liquid metal and metal that cools down again," says Dr.-Ing. Maik Brehm, who is responsible for the ROAD3D project at Merkle & Partner. "The bottom layer has already cooled down considerably, while the layer on top melts at up to 1,250°C and contracts as it cools. Similar to a bi-metal strip, stresses and constraints arise within the component. These must be made controllable."

According to Brehm, many effects can already be reproduced in the simulation in the tenth of a millimeter range. For example, the cooperation used simulations to identify flaws in components that can also be found in real-life tests when examined closely. The solution for avoiding them can lie in a wide variety of process-relevant factors: Printing speed, build room temperature, the flow rate of the inert gas, the exposure strategy of the laser and the design of the support structures of the component to be printed as well as its cooling time. These factors are tested virtually in advance as part of simulations. The correct settings can be identified via these virtual pre-tests. In this way, real test prints can be greatly reduced. Printing times and corresponding waiting times are also reduced. Thus, the simulation of different variants offers enormous advantages for design engineers.

"Within the first year of the cooperation, we have already been able to gather important results and develop calculation methods that enable simulation and thus more professional implementation of 3D printing for safety-relevant components," says Brehm.

In the second half of the project, the focus will be on strength assessment. Here it is important to take into account the special characteristics of 3D-printed components, such as residual stresses or direction-dependent material properties.