Hose reel

Task / Calculation

The construction of offshore wind farms is usually associated with considerable intervention in the landscape, as well as noise-intensive construction measures. When anchoring the wind turbine foundations, steel piles are driven more than 30 meters deep into the seabed. Each impact causes a sound wave that can be heard for kilometers underwater. This noise disorients sea creatures, which use their hearing to navigate, among other things. In addition, as with humans, the noise can cause hearing damage and stress, which should be prevented at all costs.

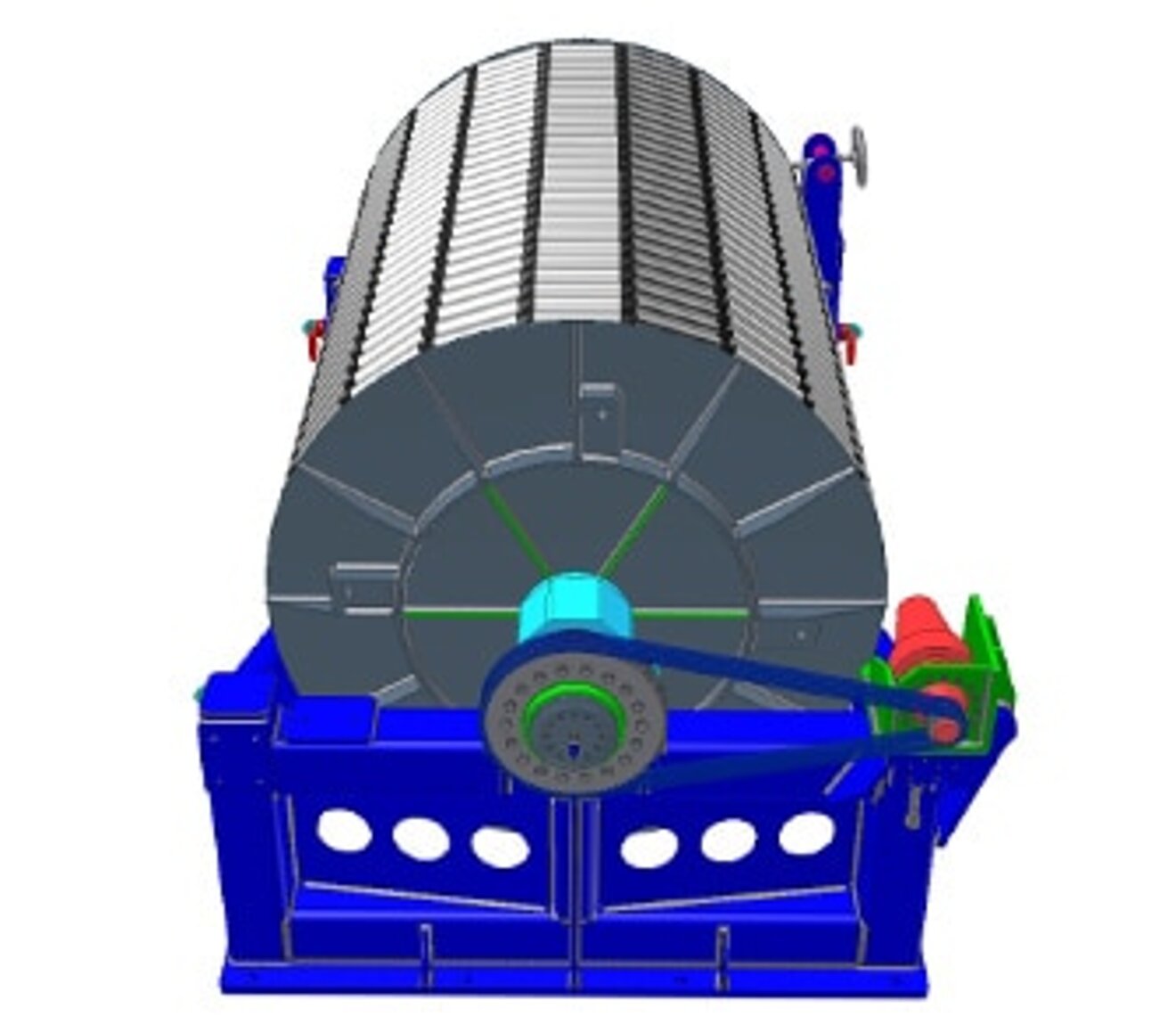

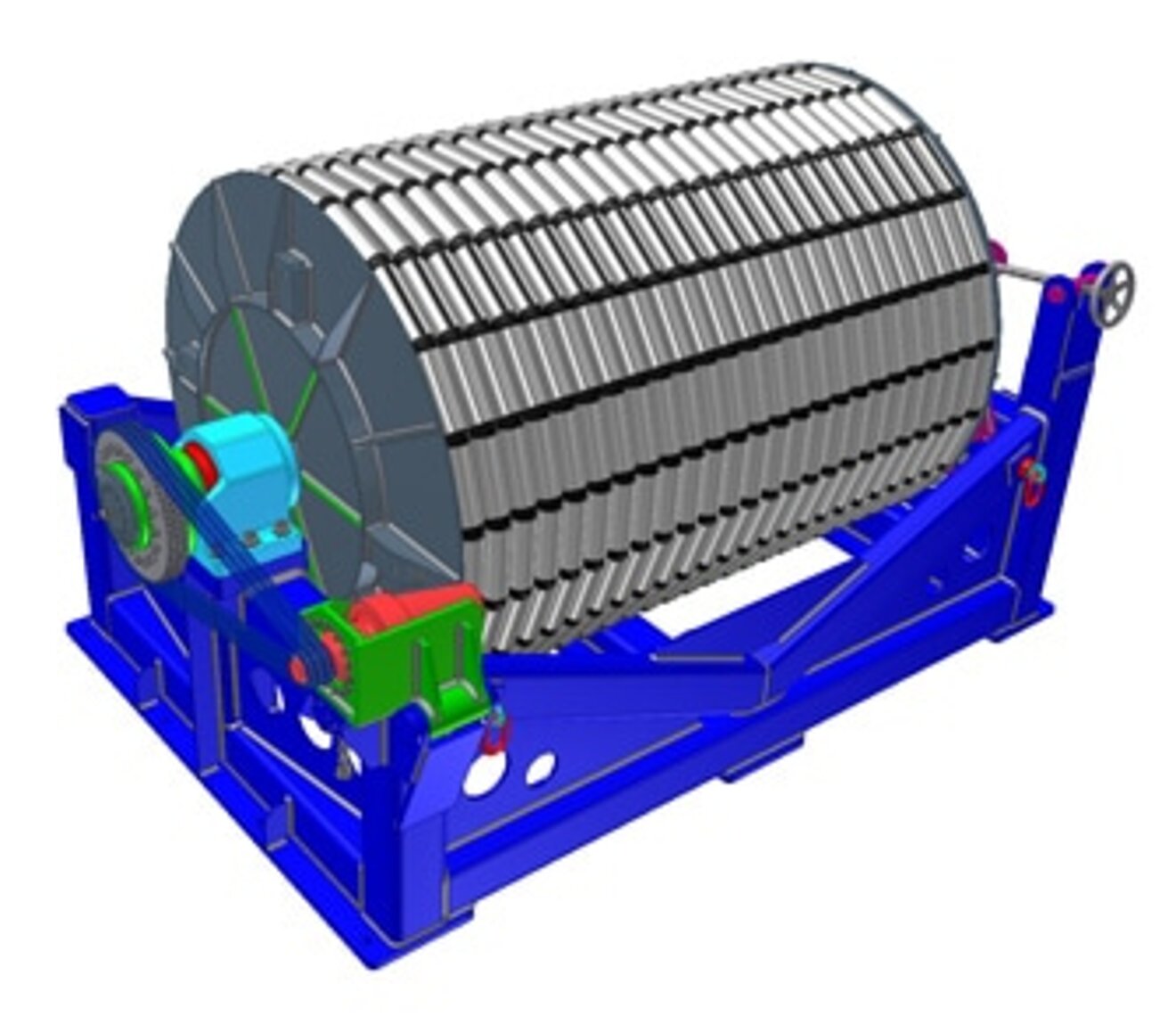

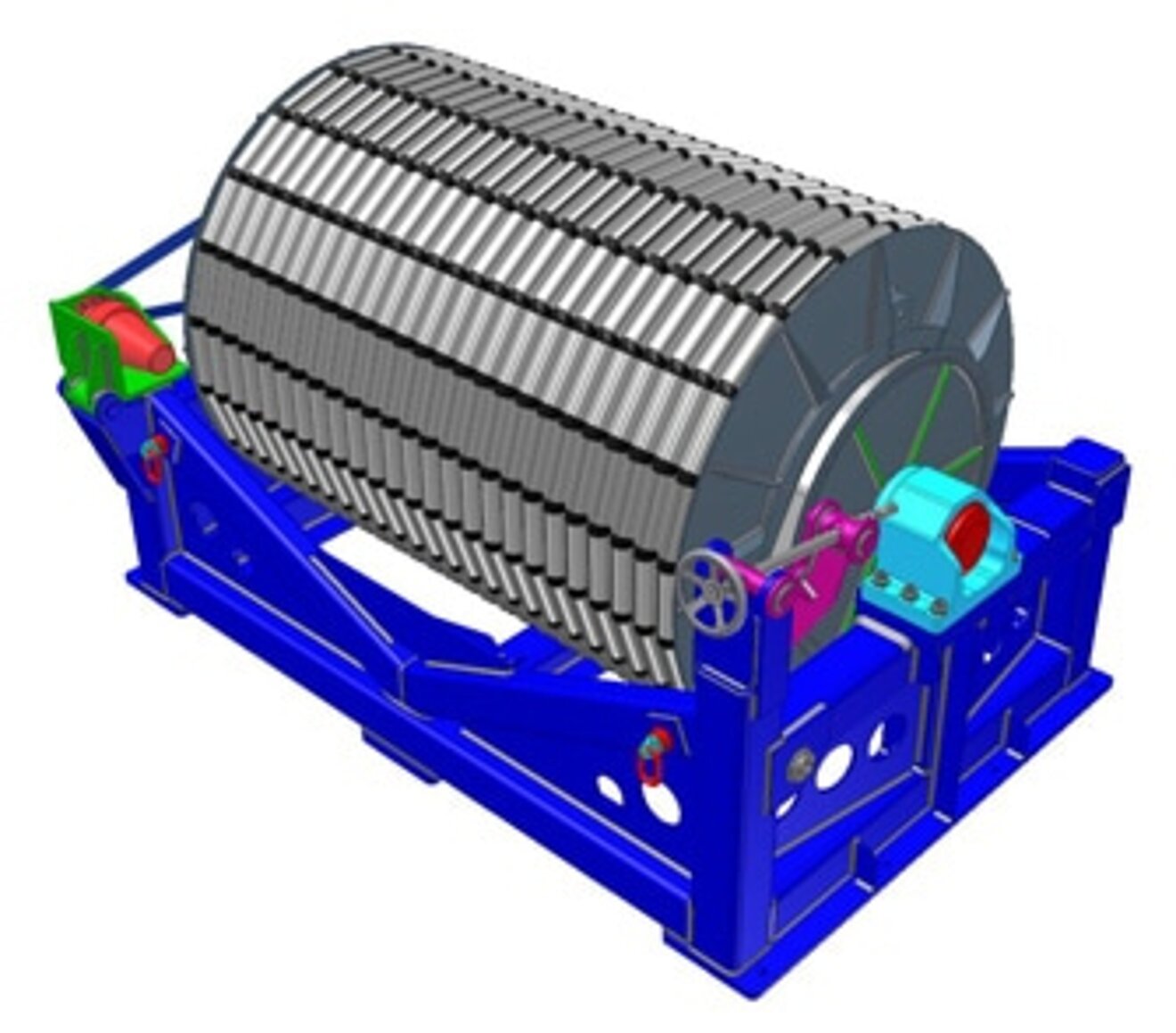

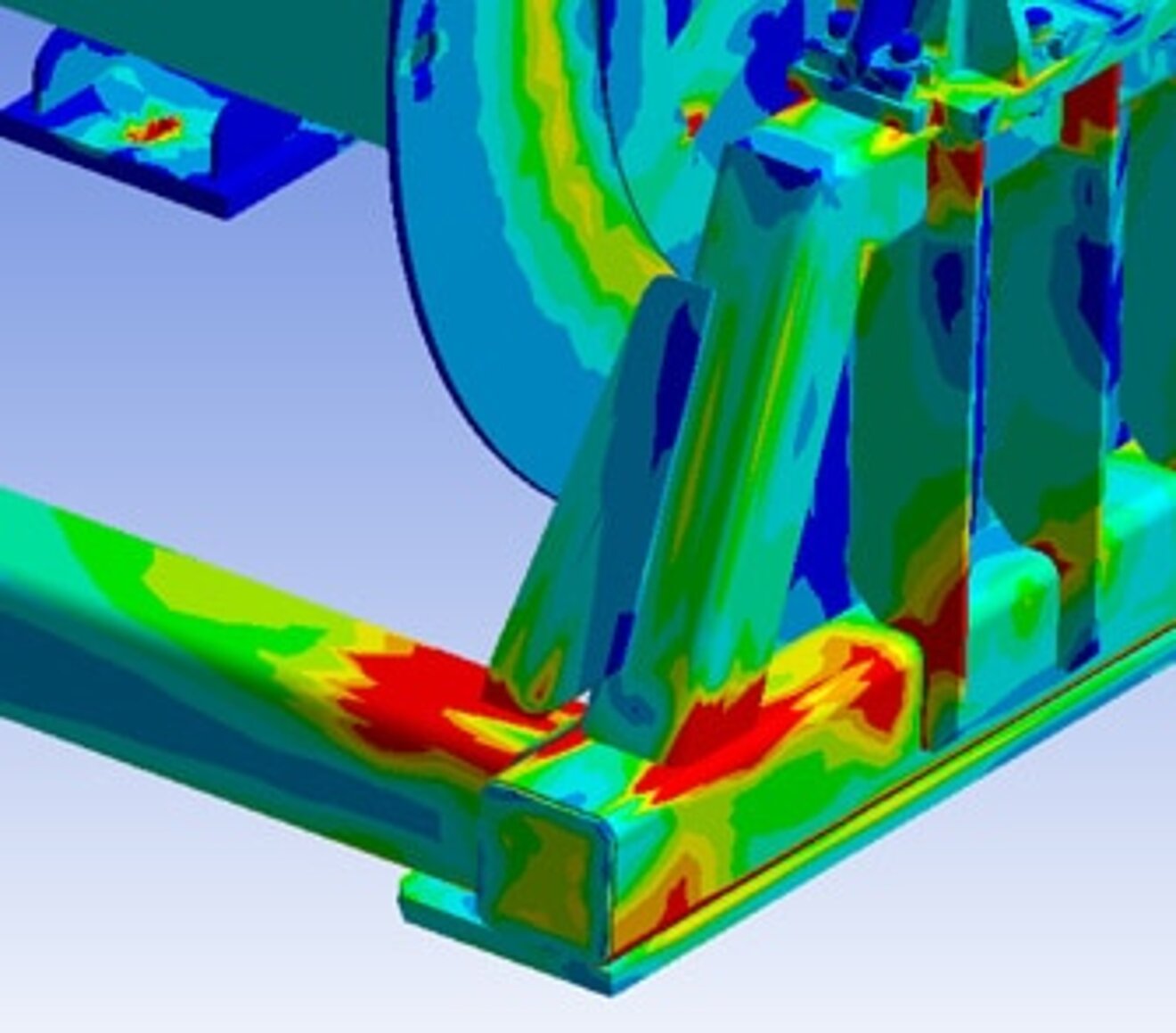

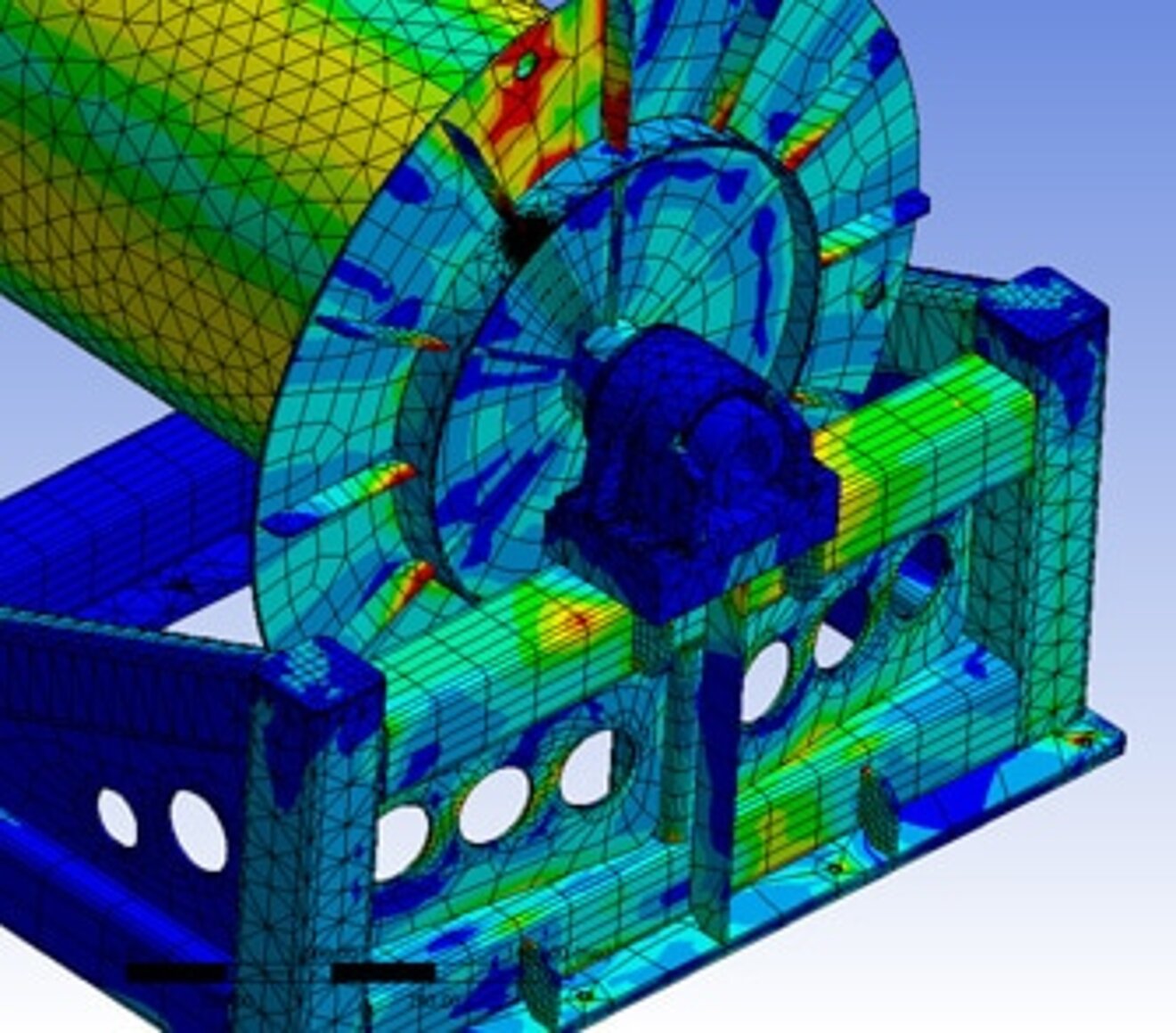

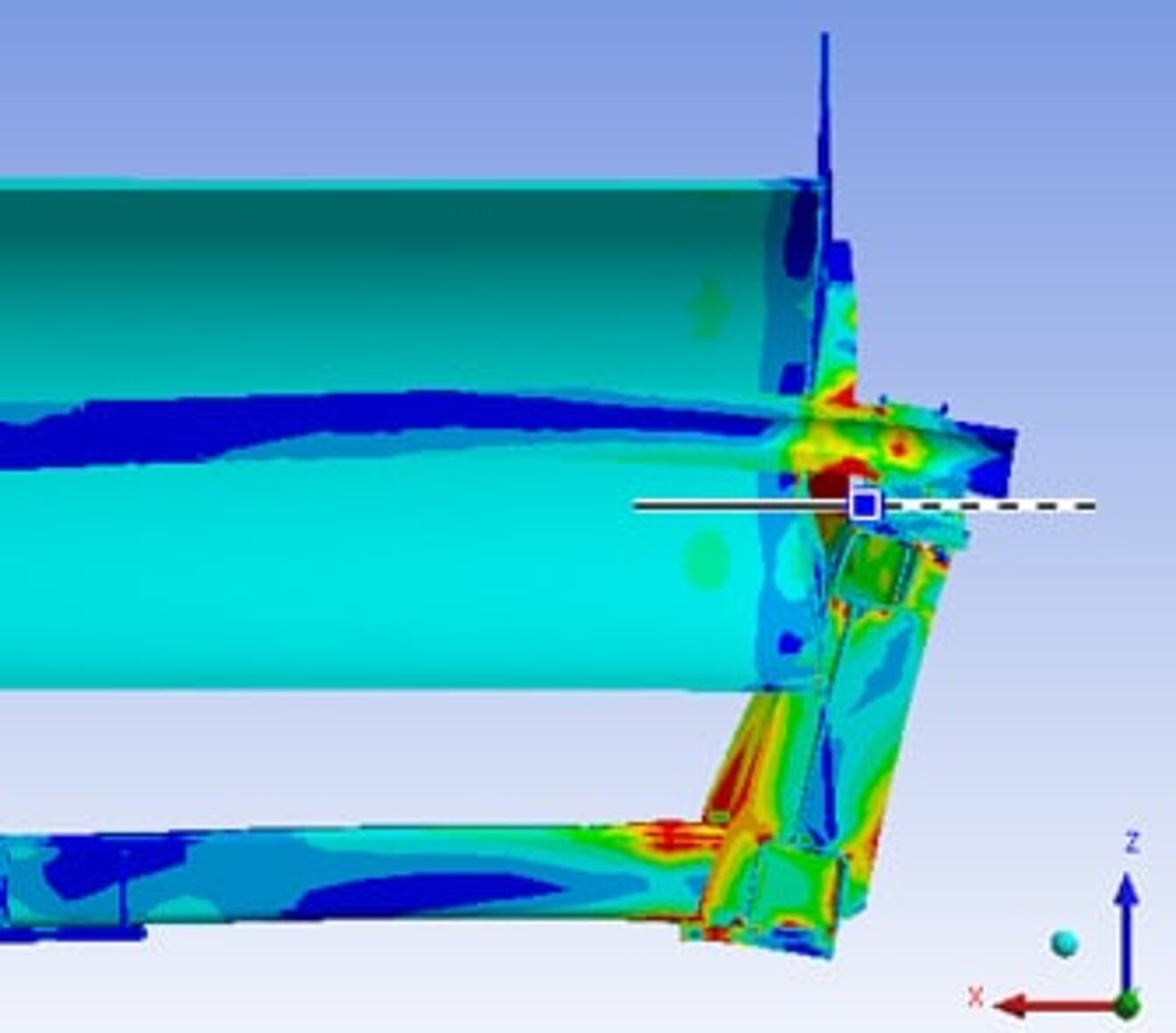

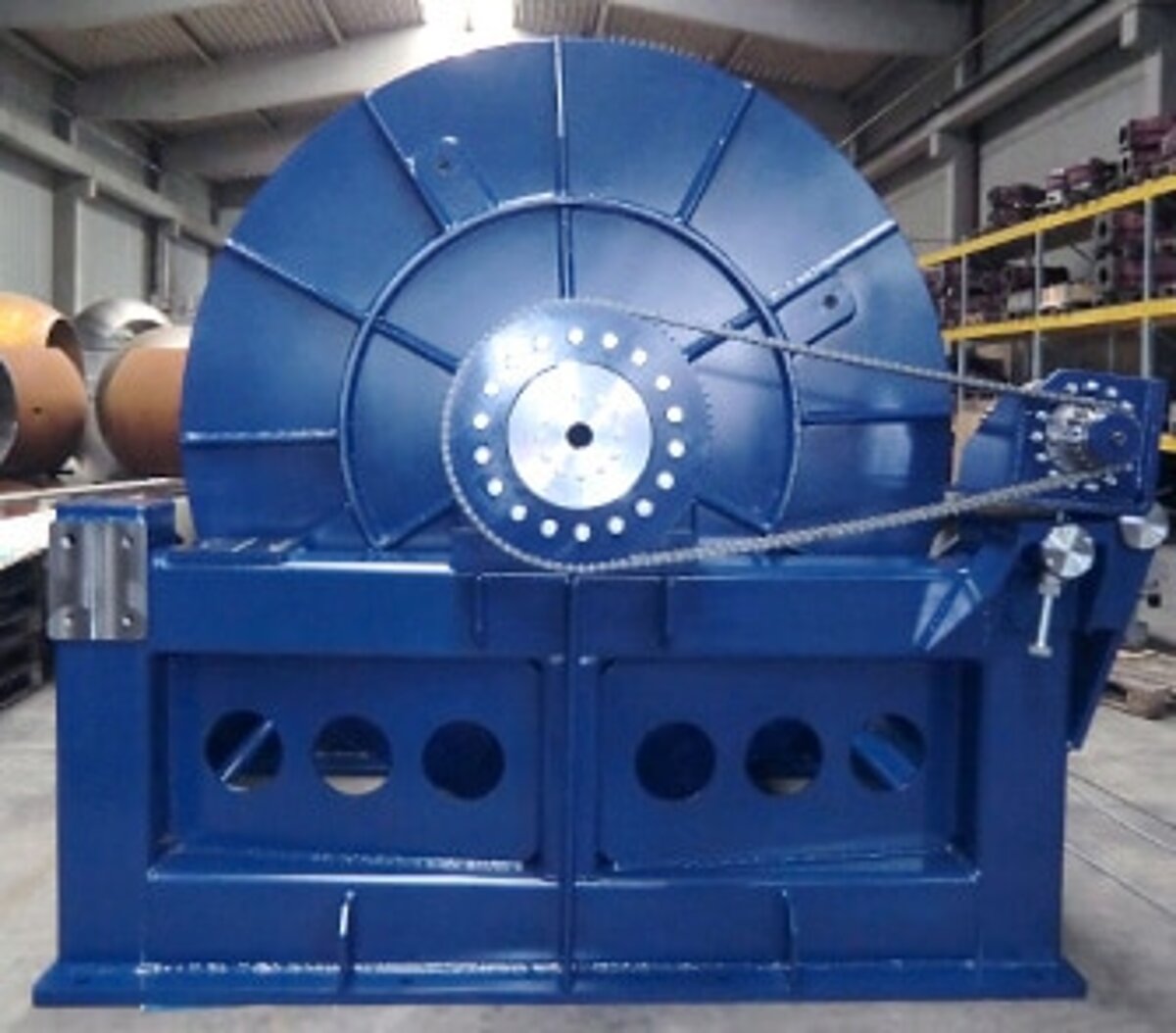

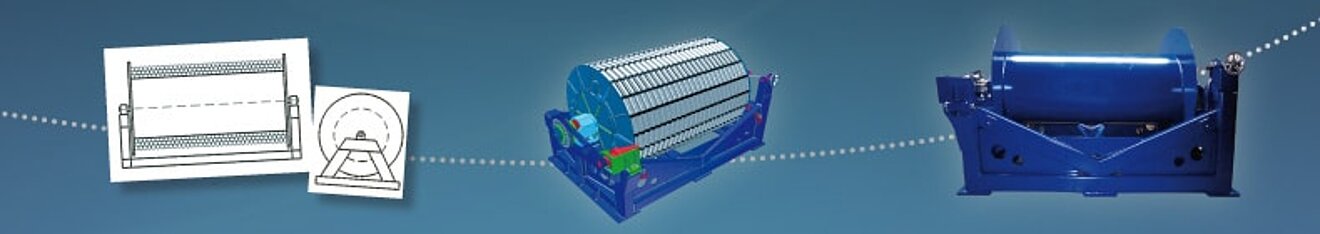

A new type of bubble curtain, which is placed around the noise source, is intended to decisively attenuate this sound. For this purpose, a compressed air-filled nozzle hose is laid out by ship on the seabed around the construction site. The client, who turned to Merkle & Partner, required a hose winch for this purpose in order to store and transport the approximately 500-meter-long hose (weight approx. 10 kg/m) on the ship, as well as to deploy and retrieve it. In order to be able to realize this, three hose winches were virtually constructed in the shortest possible time according to the requirements, calculated by means of an FE model and designed according to the corresponding standards, and the complete production was accompanied up to delivery and assembly.

Results

- Development

- Construction

- production

- regular quality control

- logistics to the place of use

- professional assembly