A great deal of testing is carried out, animal experiments are performed, and complex, lengthy and expensive clinical trial series are conducted on humans until products are allowed to be used.

Medical Devices

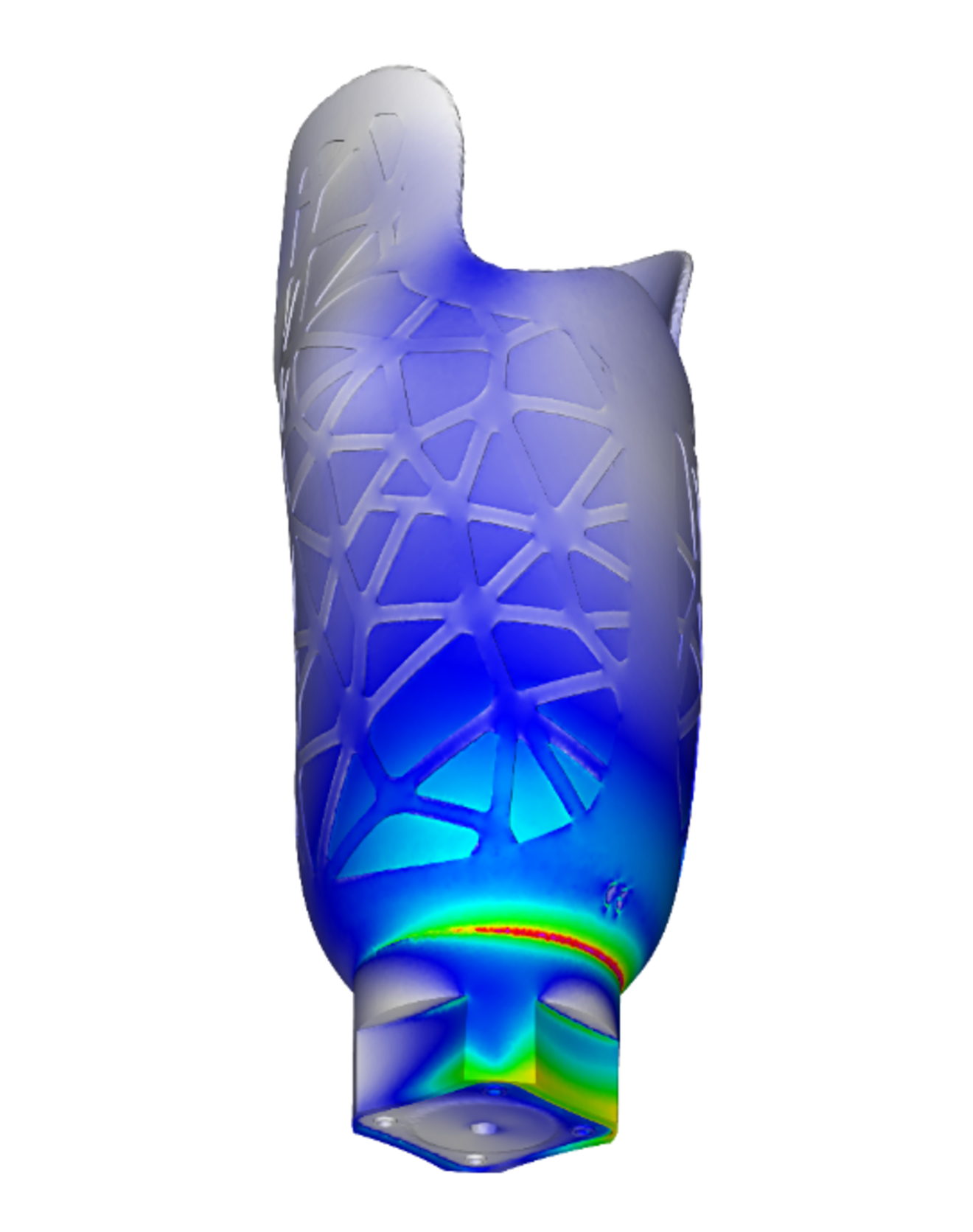

If you look at prostheses, for example, they are handmade by prosthetists. Critical ones are reinforced based on experience and cases of damage. The shape of the residual limb is scanned, but the purpose shape (range of motion), elastic areas, or reinforcements of the socket tend to be arbitrarily placed.

If the prostheses are printed via 3D printers, there is little empirical data on tolerable stresses. The load distribution, which essentially determines the wearing comfort of a prosthesis, is largely unknown.

How security is bought

These development processes for medical technology products are very complex, expensive and also unsafe. Safety is often bought by the fact that components are oversized or have to be replaced after too short a time. Interactions with humans are evaluated by means of tests. This costs time and money.

What can a simulation look like?

Simulations, both in flow calculations CFD and in the strength area FEM can greatly accelerate the development processes.

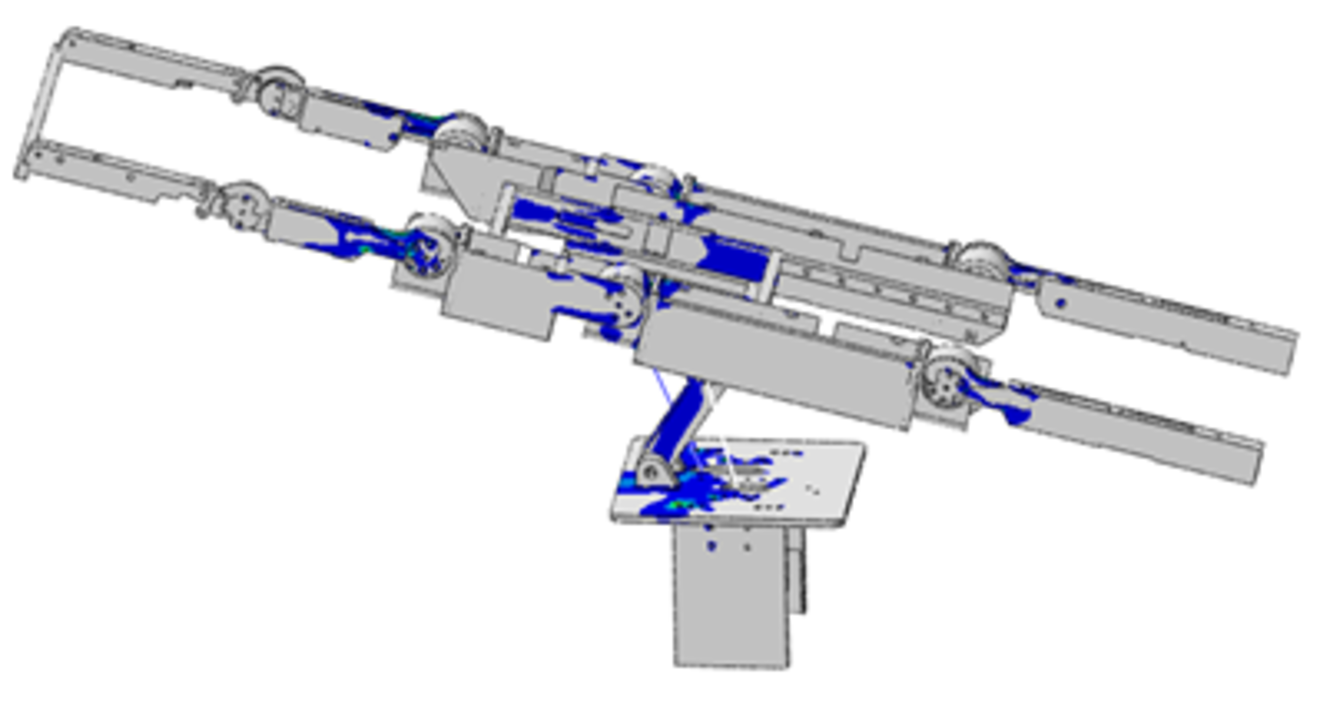

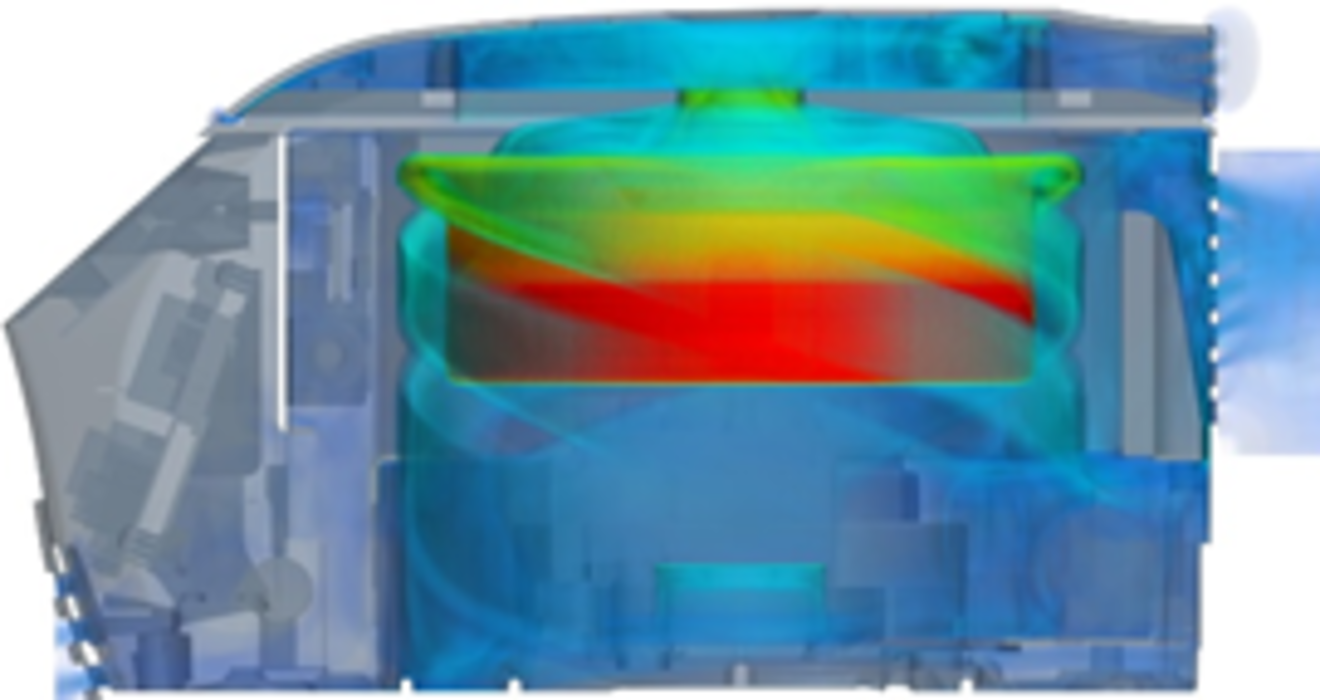

Simulation can be divided into purely technical simulations, such as an operating table, an operating light, forceps, a pump or a syringe, and simulations involving interactions with human bodies.

Examples here include wound dressings, decubitus mattresses, exoskeletons, prostheses, stents, and implants.

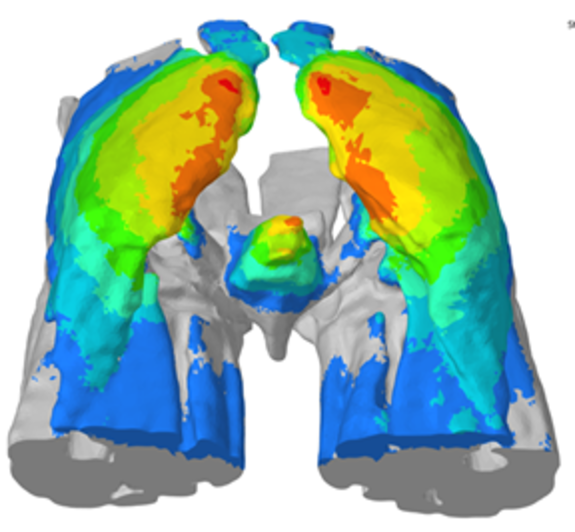

In the meantime, there are body models or partial body models for finite element studies that can accurately represent bones, muscles, tendons and skin. Here, too, the automotive industry is far ahead, using detailed body dummies for its virtual crash tests.

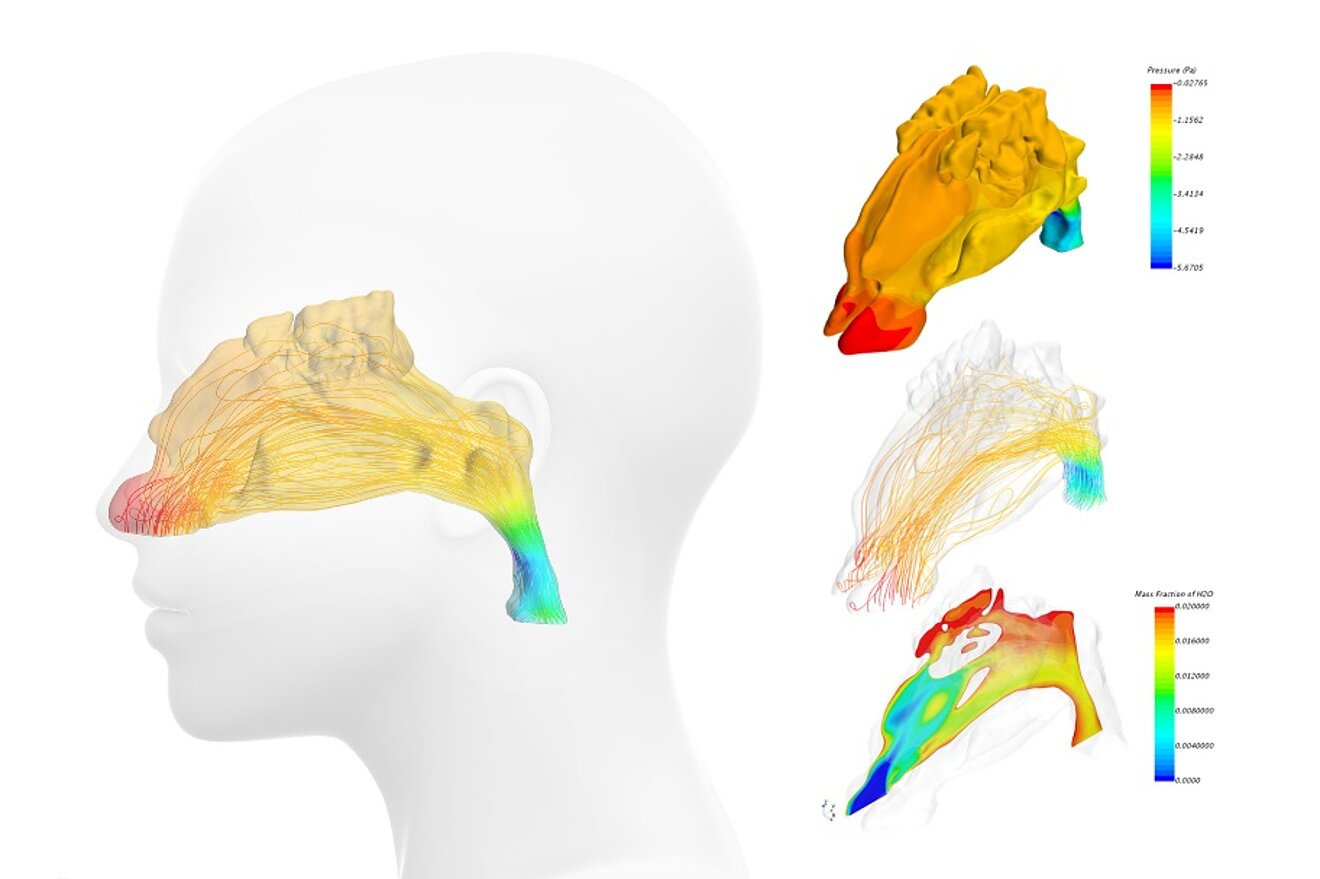

However, it is also possible to use X-rays, CT scans and MRI scans to specifically create the conditions of an individual patient as an FE model and perform various calculations.

As described in more detail in a blog article, a CT scan of the nasal cavity can be used to draw conclusions about how successful rhinoplasty, in which parts of the nasal septum are removed, is in terms of freer breathing.

What are the advantages of simulation

The advantage of simulation is, on the one hand, that the invisible becomes visible, such as the pressure distribution of a residual limb in a prosthesis socket or the flow conditions in an endoscope. On the other hand, the load on the body or technical component can be determined and compared with permissible values.

This information can be used specifically to optimize components, make them lighter, safer and more comfortable, and increase their service life.

Note

Merkle & Partner is a network partner of Space2Health, a network that combines solution approaches from medicine, medical technology and aerospace.