With efficient product development to market leadership

Faster, cheaper, safer: This is how Leifheit relies on FE simulations in the development of the "Dry&Clean" window vacuum cleaner

For more than 55 years, Leifheit AG has been one of the leading suppliers of household products in Europe. With the "Dry&Clean" window vacuum cleaner, the company has been offering a flexible product since 2015 that can be used to effortlessly clean windows, tiles and mirrors without leaving streaks.

Leifheit relied on the simulation expertise of Merkle & Partner for numerous details of product development. A decisive advantage here was speed. This meant that different design variants could be simulated simultaneously. New modifications could be checked promptly on the calculation model. Based on the calculation results, the safeties with regard to strength could be efficiently determined and optimized. In contrast, tool adaptations for the production of new prototypes would have been very cost- and time-intensive.

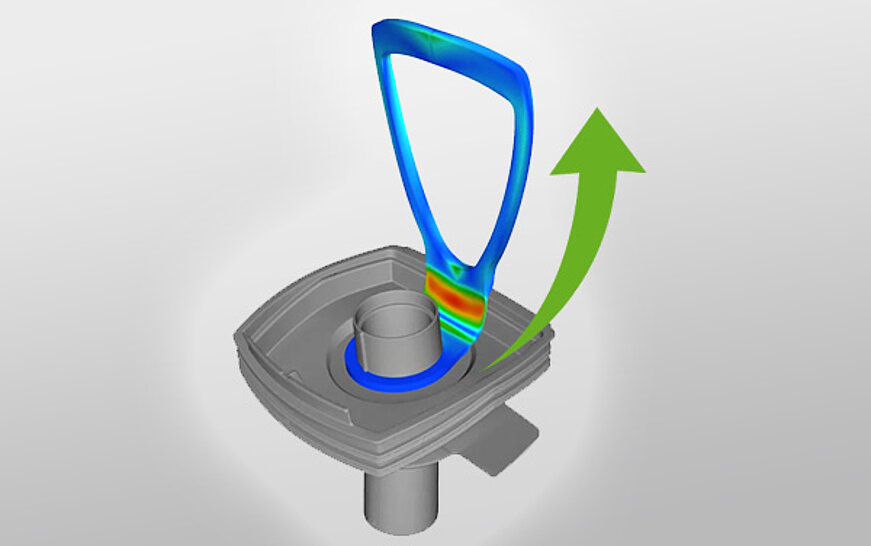

A polypropylene tab is used to pull the sealing element out of the liquid container. The fastening ring and the grip tab are connected by a plastic film only approx. 0.8 mm thick. The molded part lies at an angle of 45° in the product. In the application, the tab is first bent up to an angle of 90°, after which it is pulled.

It took around 10 working days to find the optimum geometry variant that met the requirements for compliance and strength with the aid of several simulations. First, the initial variant was calculated, followed by recommendations for improvement, and then a further three variants were recalculated.

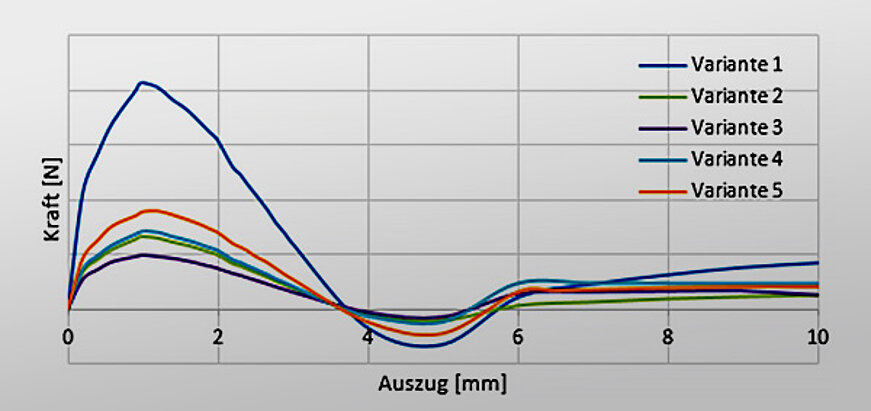

For consumers, the feel is of utmost importance. The removable suction cup should sit as firmly as possible in the adapter's spring. The assembly and disassembly forces should therefore be as large as possible. Simulation was used to investigate the stresses occurring for the final assembly and disassembly states in terms of strength.

From the recalculation of the initial variant to the final geometry variant, the project duration was only 10 working days. The challenge here lay in the stress field between the greatest possible pull-out force while at the same time complying with the maximum permissible stresses.

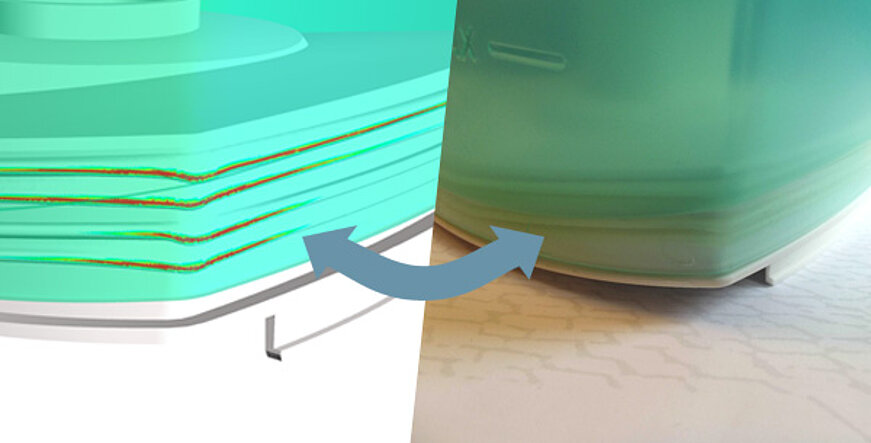

A TPE seal located between the tank lid and the tank must ensure tightness up to a water column of 50 mm.

Different variants were tested with the aid of simulations. The validation tests showed very good agreement between the simulation results and the real tests.

Pre-damage avoidance

The assembly of the fan impeller of the window vacuum cleaner is of particular importance. The plastic impeller is pushed onto a toothed shaft and then tested in continuous operation. Pre-damage should absolutely be excluded during assembly.

Simulation was used to determine the plastic strains during the assembly process. Based on the results, significant pre-damage could thus be ruled out.

With kind permission of

Leifheit AG

Do you have similar tasks or questions about this article?

Do not hesitate to contact us!

Contact Merkle & Partner ‣