Structural analysis of a feed tray

Task / Calculation

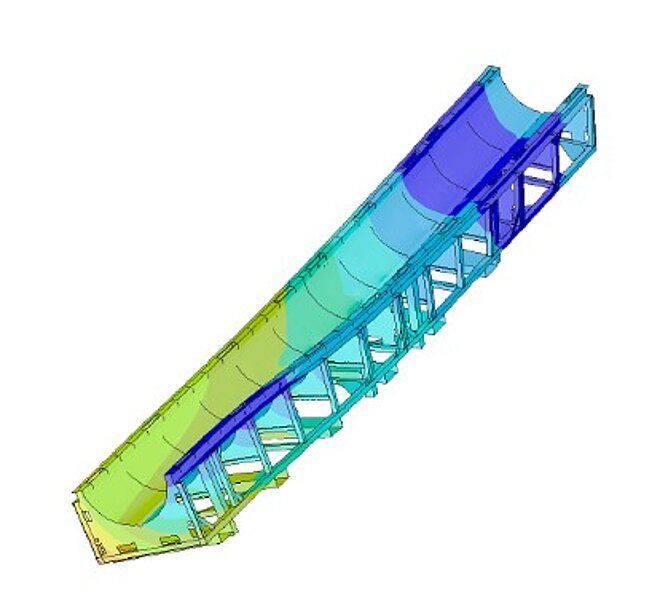

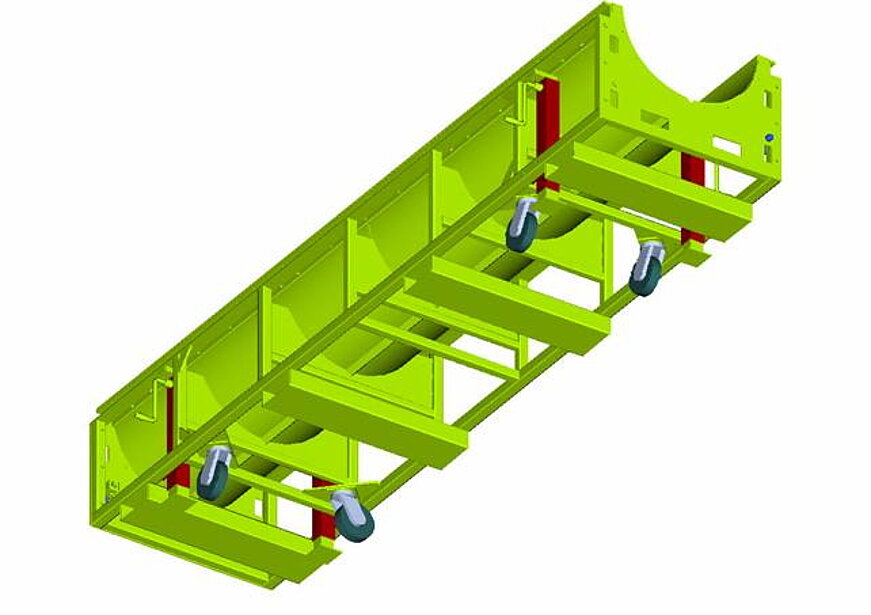

A slide-in trough for test specimens was to be analyzed and, if necessary, optimized using the finite element method with regard to the deformations and stresses occurring under various loading situations.

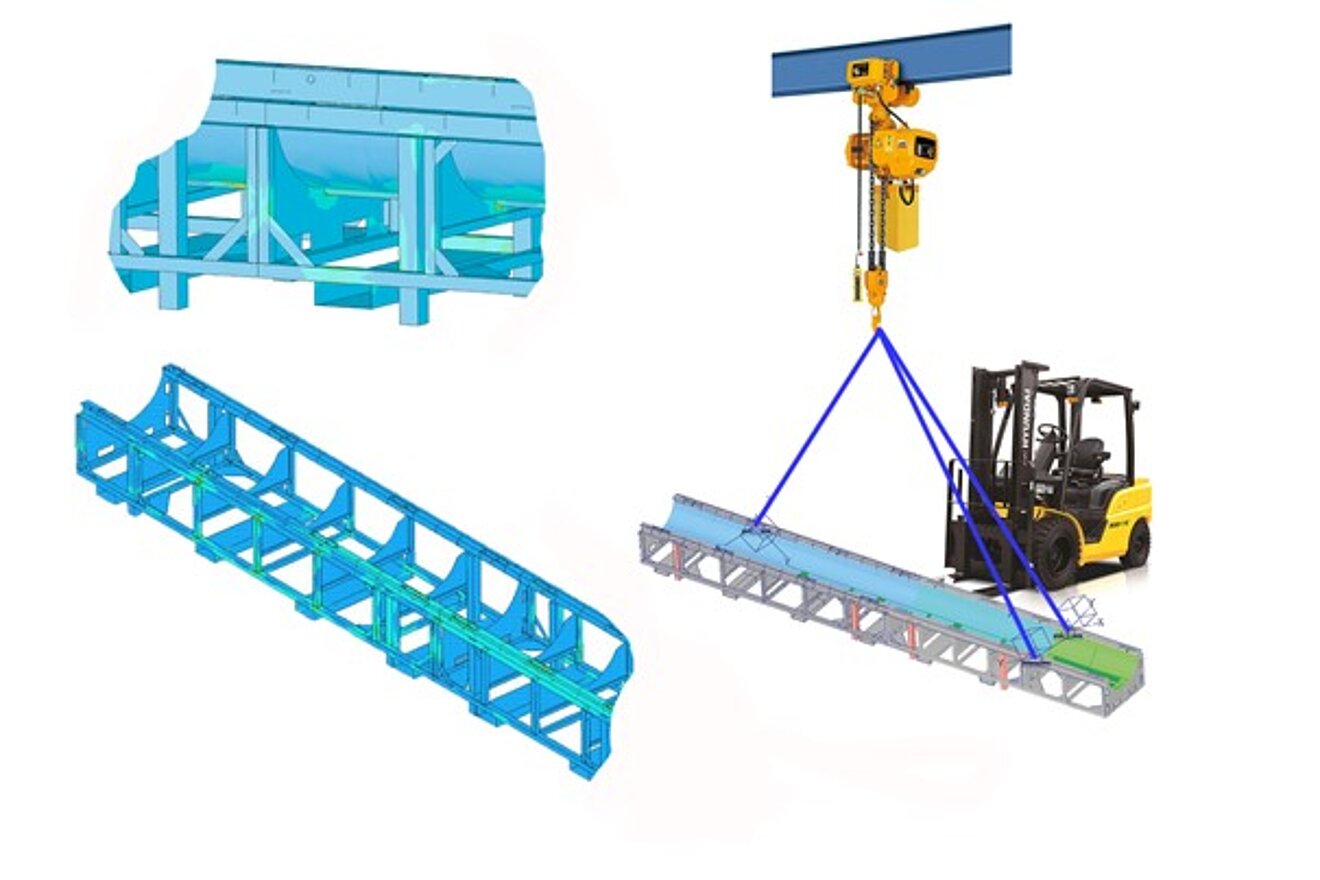

Depending on the diameter and configuration of the test specimens, the 4.5 m long trough had to be extended with additional modules of 2.5 m and/or 1.5 m. The trough is suspended from the crane. The trough is transported suspended from a crane or via a forklift. Various load situations occur during transport and operation.

Goal / Benefit

The aim of the investigation was to dimension bolts, to identify weak points at an early stage, to investigate and evaluate the effectiveness of specific measures by means of optimization investigations, and to provide the static strength verification for the final design.

Results

Within the scope of the task, all load situations were simulated and the critical configurations determined. The critical areas were identified and the forces in the fasteners were determined.

The initial investigation revealed unacceptable values and overstressed weld seams or unacceptably high stresses in the transport loads at some points. Through various optimization measures, these critical stresses could be reduced by up to 57%.

The static strength verification could finally be provided for the operating conditions and for the forklift transport.

At a welded joint between the lower longitudinal girder and a vertical support, minor stress exceedances still occurred mathematically. However, this in no way meant that damage could occur here. On the one hand, the selected load increase factor of 2 was to be judged as very conservative. The stress determination concept also represented a very conservative consideration.

The allowable stress of a weld is essentially influenced by its quality. In our opinion, it was therefore sufficient to ensure that these welds were of high quality and, if necessary, to overgrind them. By making sensible simplifications, it was possible to optimize the initially somewhat complex structure, with the result that the weight of the tub in the final version was 20% lighter.

Even after almost 20 years of operation (the project originated in 2002), the infeed trough still performs its service without any problems.

Summary

The critical load cases in the recalculation of the design of a sluice tray occurred during transport by crane and forklift.

The design was simplified and optimized to such an extent that the verification could be reliably performed even if the permissible stresses in a weld seam were slightly exceeded. The maximum forces from the FEM model were used to dimension the bolted connections.

The critical stresses could be reduced by more than 50% and the weight of the trough reduced by 20%.