Fiction and truth - what mistakes you can make when designing seals

For a building seal, we had the task of developing a seal in such a way that when it is installed on the construction site, the squeezing of the seal indicates the tightening torque of the screws.

Understandable, since construction workers don't usually have a torque wrench in their construction trailer.

Based on rough models, in which the hyperelastic (incompressible) behavior of the rubber was estimated by us using the Shore hardness 50 Shore A for the first simulation (FEM), the feasibility was shown.

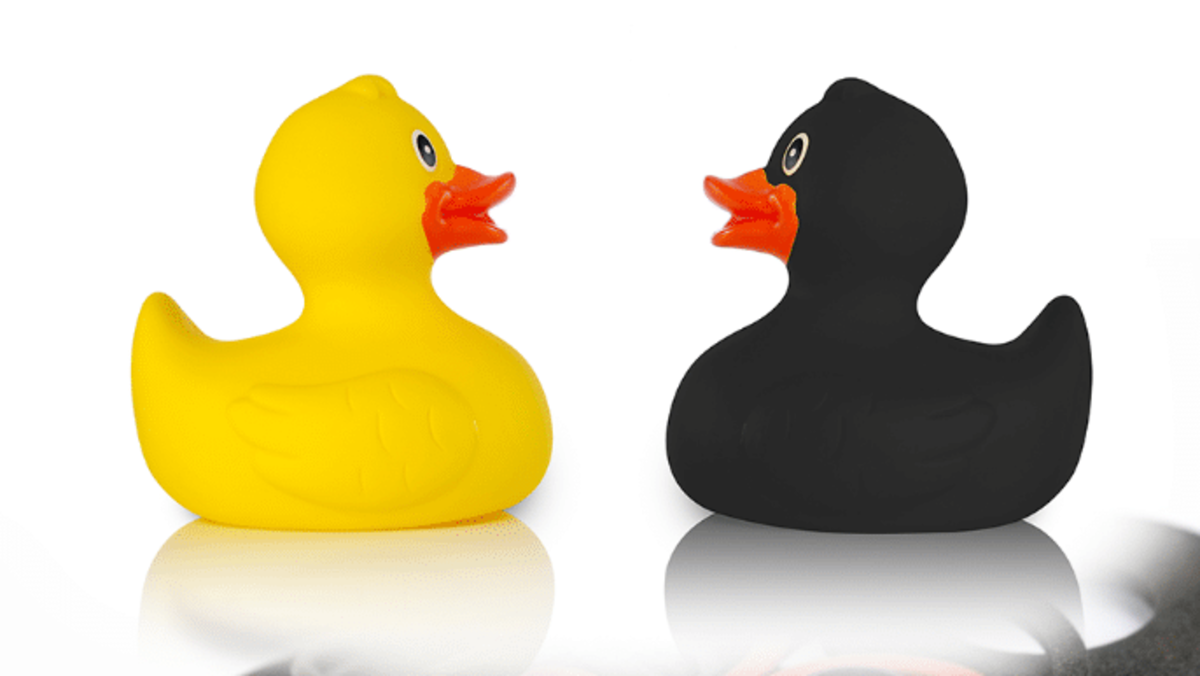

For the exact design, we commissioned various tests to determine the material behavior of the sealing material used. For this purpose, we received black sheet material, also 50 Shore A, from the customer. We then fitted the results as a material model in our FEM software (in this case Abaqus) and used them in the simulation.

Using variants, we designed the function of the gasket material so that a viewing window was just filled by the swelling rubber when the desired bolt tightening torque was reached. The bolt preload force was determined so that the contact pressure of the sealing material between the pipes and the borehole was higher than the pressure of the groundwater.

The prototype worked as desired and the product went into series production.

The surprise was great when our customer contacted us with the bad news that the first series parts did not work because they were leaking.

We then requested further sample material and were shocked: the supplied sheet material was squeaky yellow and soft. For the series, a dye had been added to the previous material to improve visibility around squeeze windows, unfortunately this worked like a plasticizer and the Shore hardness dropped to 30 Shore A.

Findings

This example impressively shows what must be taken into account when designing seals with the aid of FE simulations: Not all rubber is the same!

A derivation of the material model based on the Shore hardness is a rough approach and is suitable for feasibility statements. For a correct design, measured material properties are needed to create the material models for the FE calculation.

Additives change fundamental properties of the elastomer. Therefore, a rubber calculation must be done with a material model that not only corresponds to the correct material, but which is also adapted to the loading condition. Therefore, although we do not perform the tests ourselves, we have them under control.

Apparently similar materials often have fundamentally different behavior.

Surrounding medium, temperature and, if applicable, frequency under dynamic load did not play a role in the above example, but may have to be taken into account.

A few more basics

In engineering, seals are used to prevent or limit the unwanted transfer of substances from one place to another. Sounds turgid, but it sums it up quite well.

The substance that is normally to be prevented from passing over is, for example, water, oil, air, gas or another liquid or gaseous medium.

In the case of a refrigerator door, for example, cold and hot air are to be separated from each other.

Rubber, elastomers, PTFE, but also metallic gaskets or carbon are used as sealing media.

Gaskets are usually softer than the components to be sealed in order to compensate for differences. They are pressed, whereby the contact pressure must be at least as high as the pressure of the medium to be sealed or, in the case of a vacuum, the ambient pressure.

How we can also help you efficiently with the design of seals is best clarified in a short and non-binding conversation. Send us a short mail. We will then get in touch with you.

Your Stefan Merkle

PS: And another rule of thumb that has accompanied me for decades: After 10 years, only 25% of the preload from assembly is still present. So also take aging into account. After all, your machine should also still be tight in old age.